12-04/2025

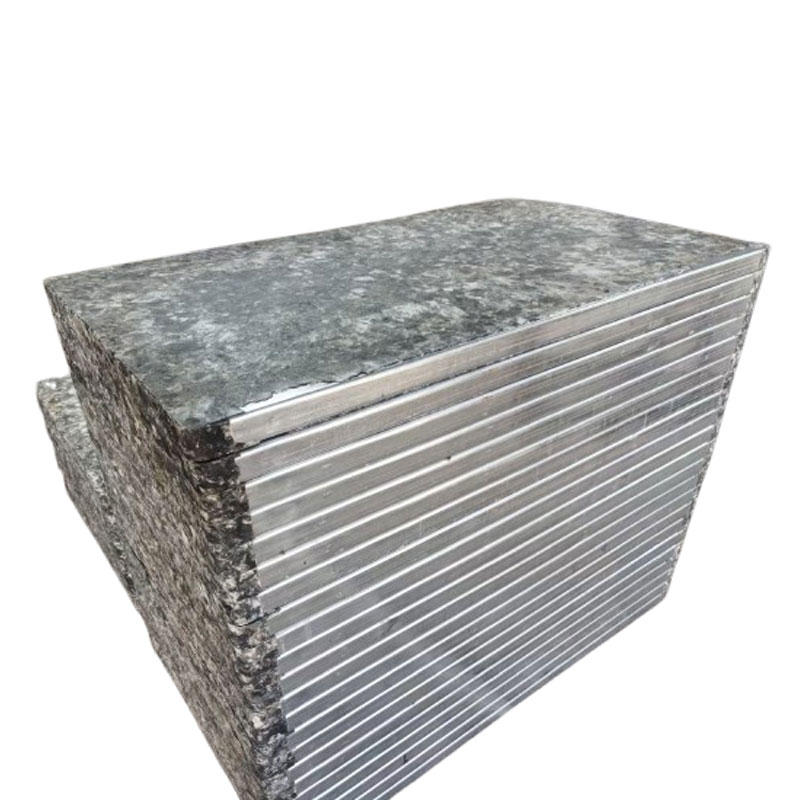

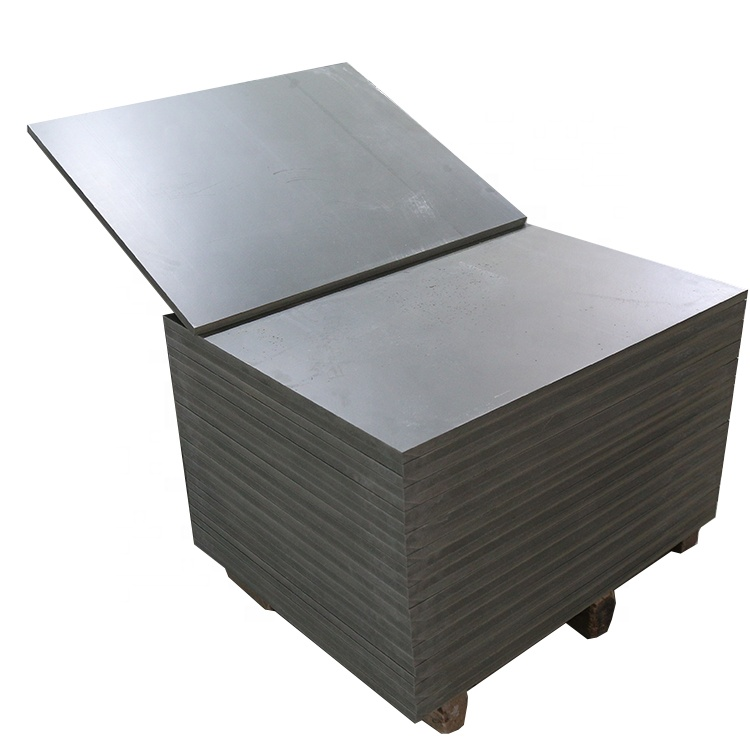

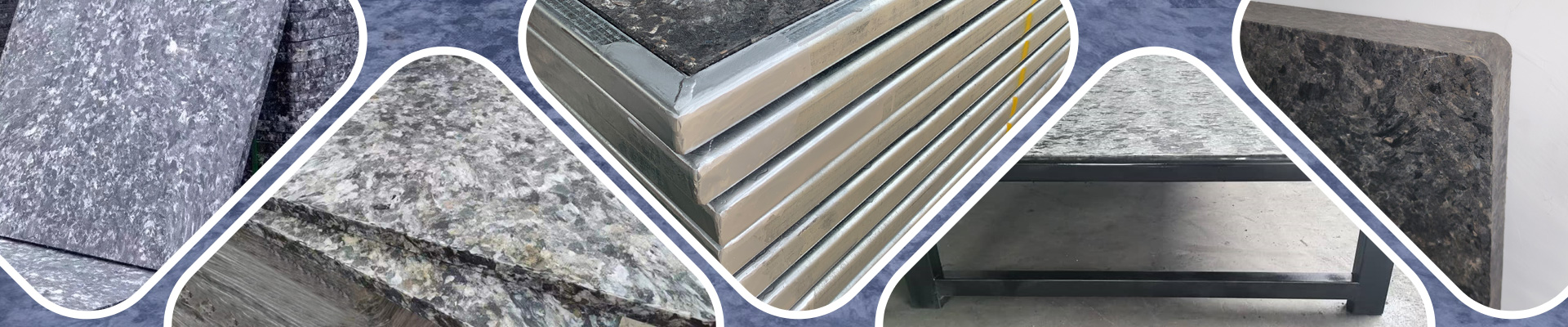

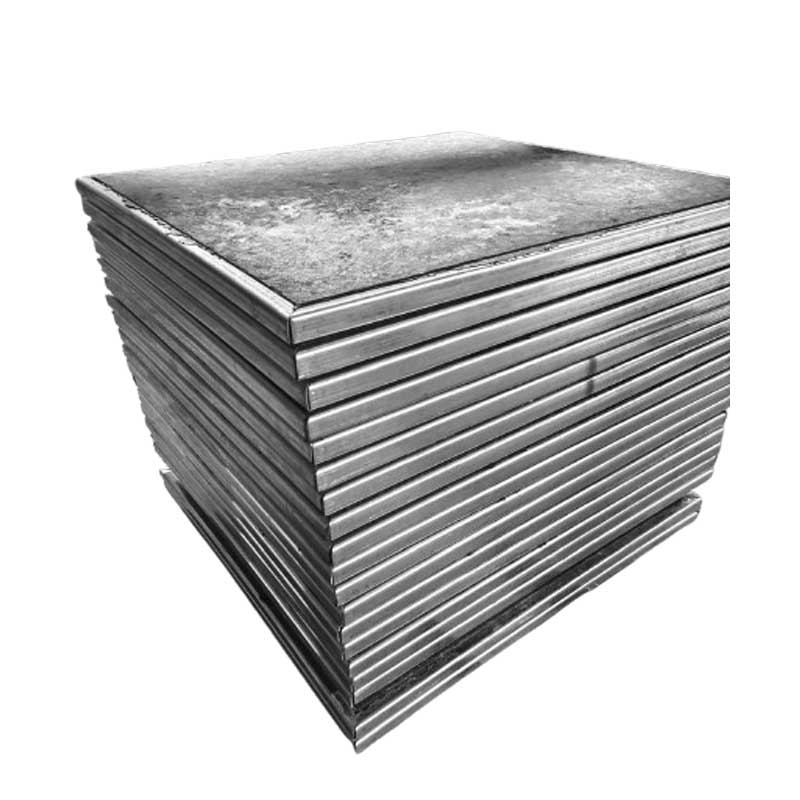

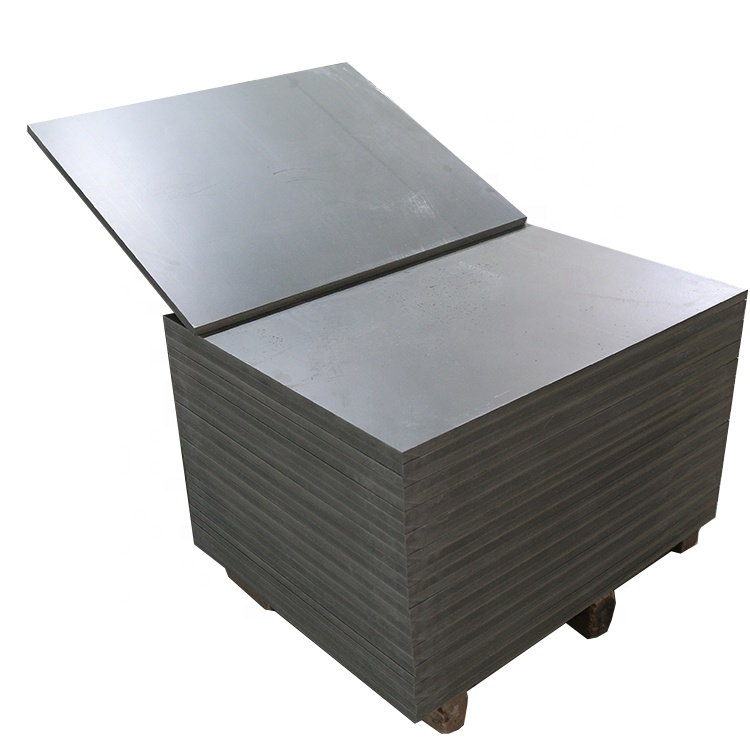

Recently, a delegation from a renowned Tanzanian brick manufacturer visited our factory for an on-site inspection and performance testing of our block machine pallet production line. This factory audit primarily focused on the manufacturing processes and quality control systems of Block Machine Pallets. The clients toured the entire manufacturing process of Steel Pallets for Block Machines and witnessed live load-capacity testing of Heavy Duty Block Pallets. During technical exchanges, both parties engaged in in-depth discussions on the compatibility design of Brick Making Machine Pallets and the surface treatment technology of Concrete Block Pallets. The clients highly praised the durability, precision, and standardization of our pallet products, laying a solid foundation for future cooperation in the East African market.