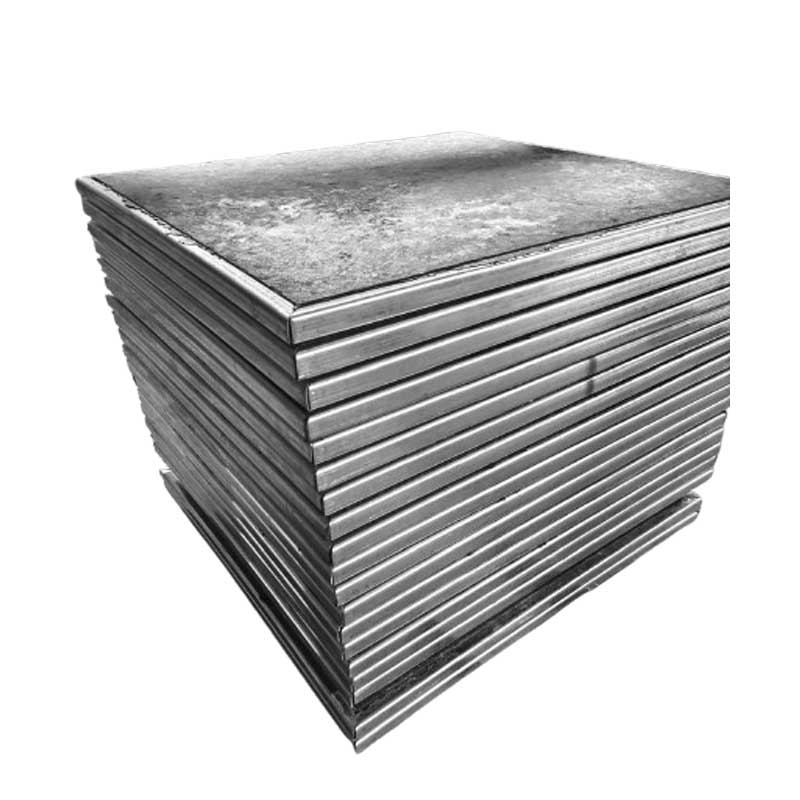

Every block machine pallet of price or cost, we produce undergoes a series of strict quality inspections to ensure consistent performance and stable block machine pallet cost for our customers.

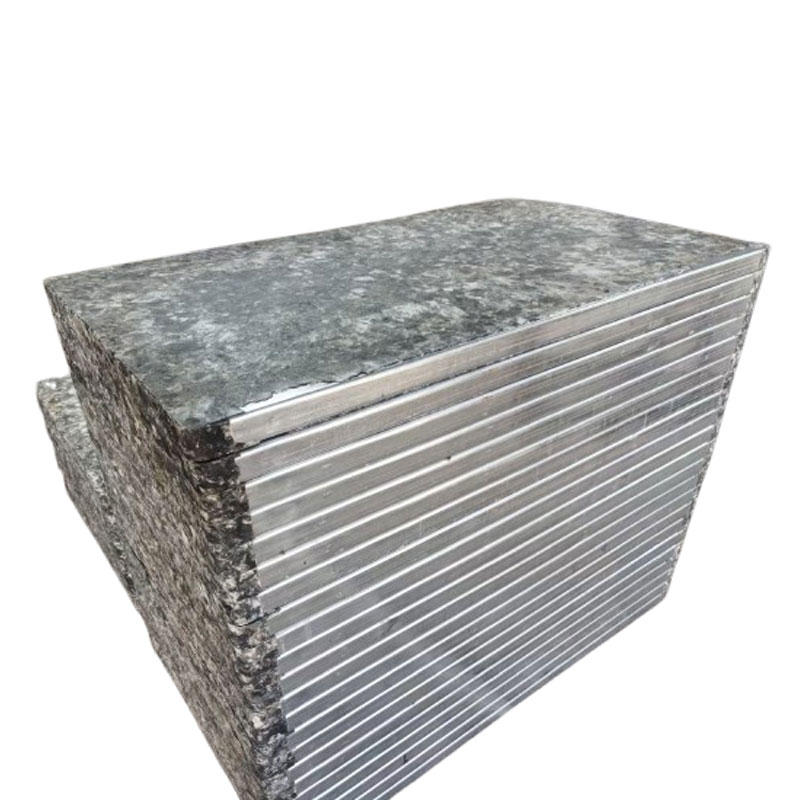

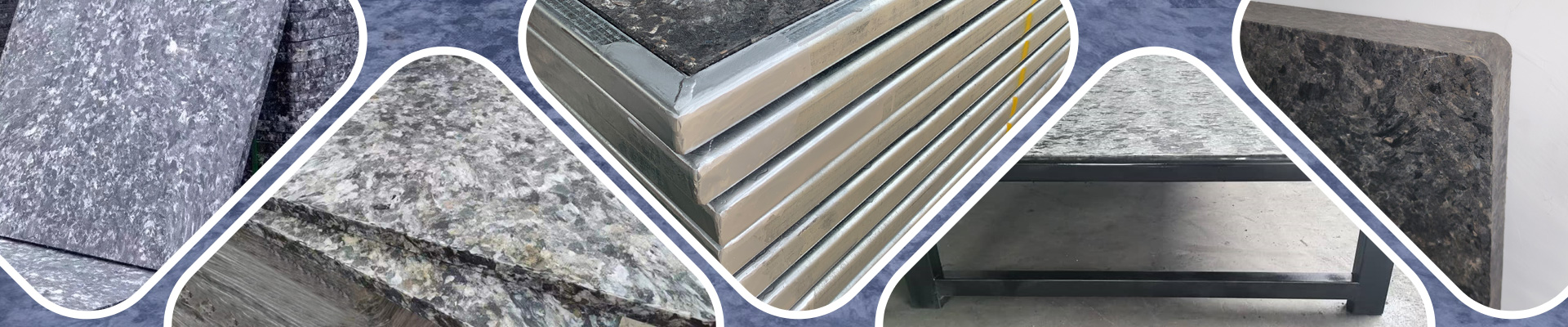

Before production, raw materials such as fiberglass and resin are precisely weighed to maintain the correct ratio — 30%, 50%, 70% or higher — ensuring each pallet meets the strength and durability requirements.

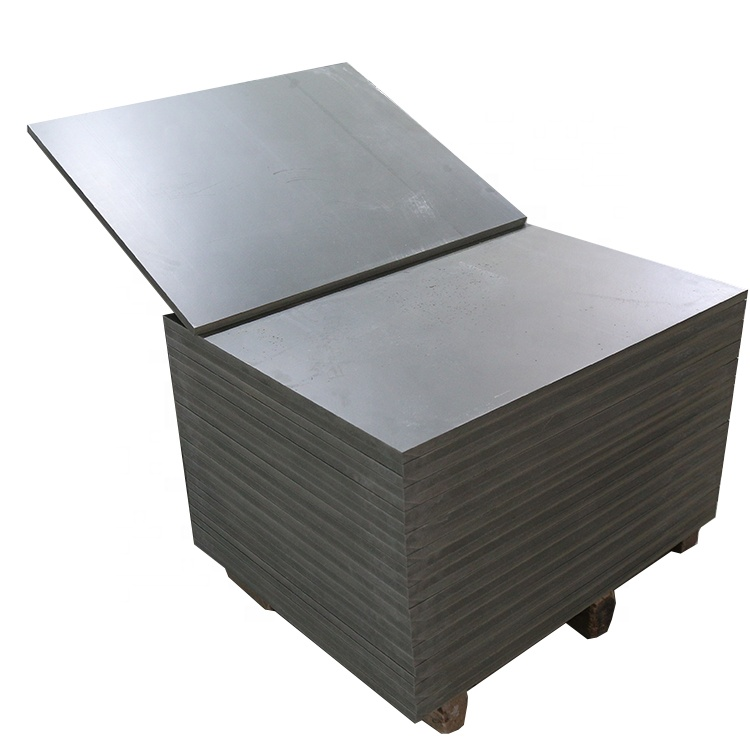

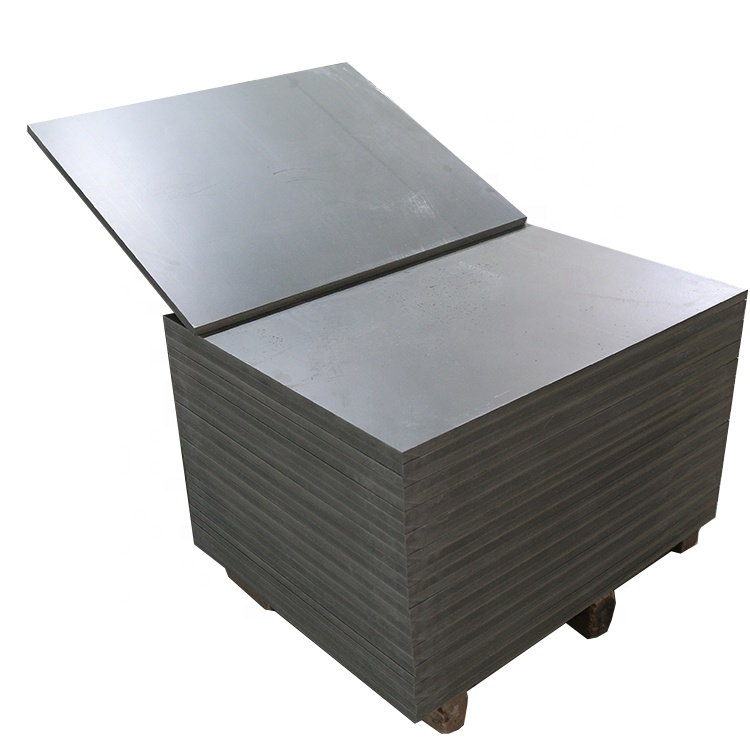

During the production process, we conduct bending tests to check the pallet’s flexibility and strength. Each finished block machine pallet is measured for length, width, and thickness, with an error tolerance within ±1mm, guaranteeing uniformity across all pieces.

Finally, our quality assurance team performs impact tests, including high-drop tests and hammer strike tests, to confirm the pallet’s resistance to cracking or deformation.

These inspections not only ensure high quality but also help us maintain a competitive block machine pallet price without compromising on durability or performance.