Tanzanian Clients Conduct On-Site Factory Audit, Deeply Evaluating Block Machine Pallet Manufacturing Capabilities and Product Performance

Against the backdrop of global collaborative development in the building materials machinery industry chain, Chinese-manufactured professional equipment continues to inject momentum into infrastructure construction in Africa. Recently, a technical delegation from Tanzania United Building Materials Co., Ltd., a well-known brick product manufacturer in Tanzania, arrived at our production base for a two-day in-depth factory audit and technical exchange. The core objective of this visit was to comprehensively evaluate our capabilities in R&D, manufacturing, product quality stability, and production capacity assurance as a potential core supplier of Block Machine Pallets.

1. Focusing on Core Products: Systematic Inspection of the Pallet Production Line

Upon arrival, the delegation first attended a thematic presentation on our company's development history and product portfolio. We emphasized the critical functional importance of Block Machine Pallets as key consumable components in automated brick production lines, whose performance directly impacts block forming quality, demolding efficiency, and overall production line stability. The clients showed keen interest and proceeded to the production workshop for on-site observation.

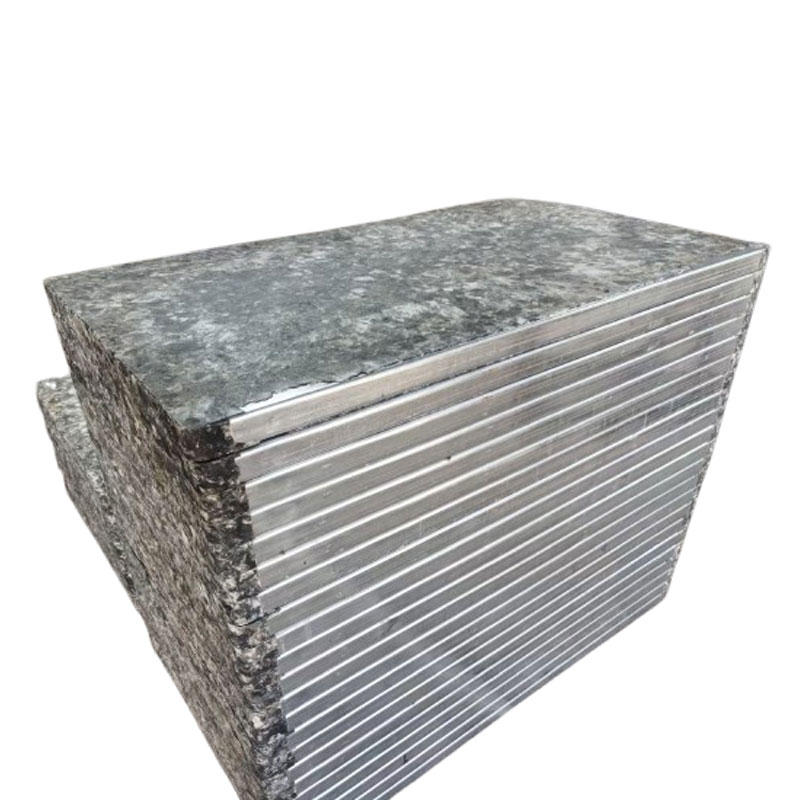

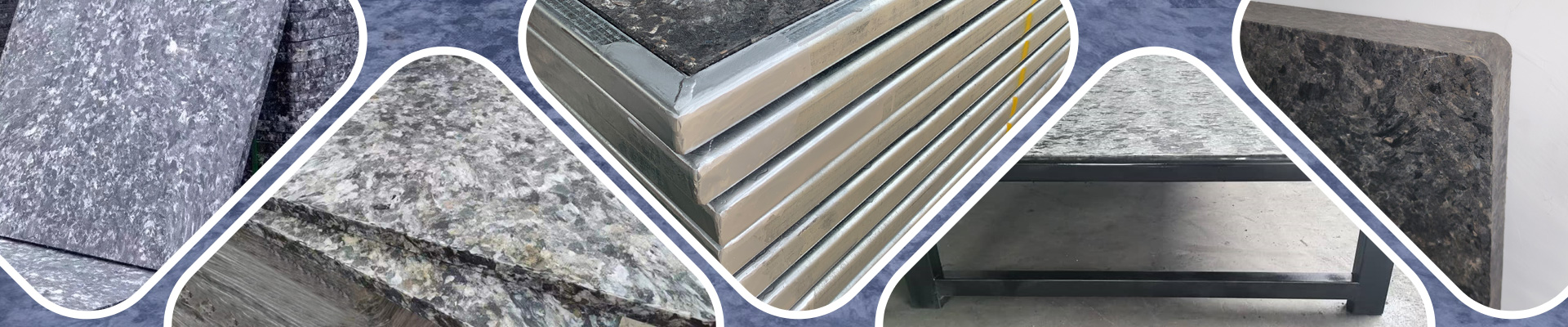

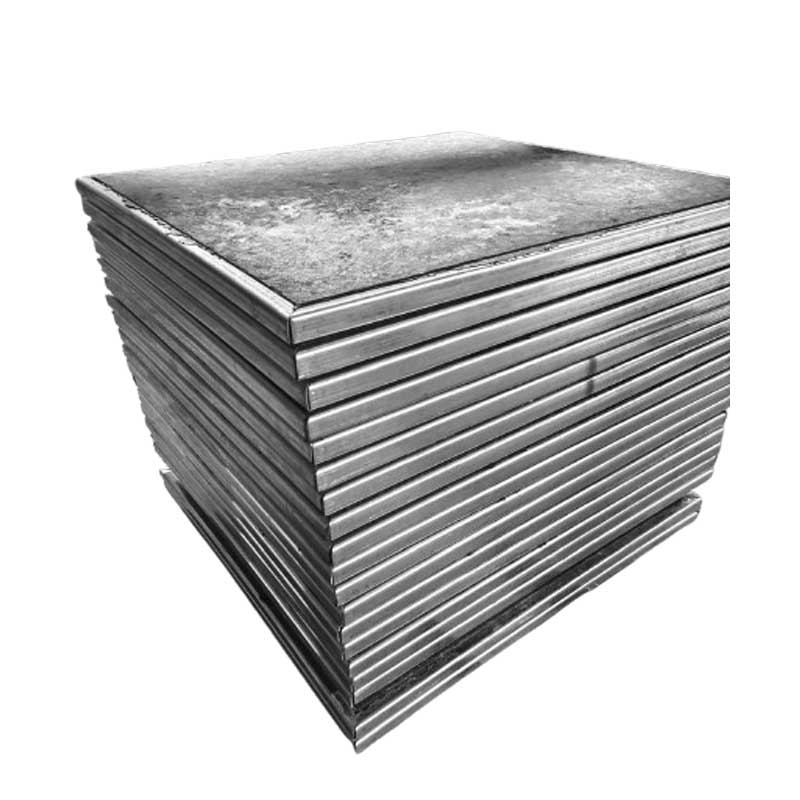

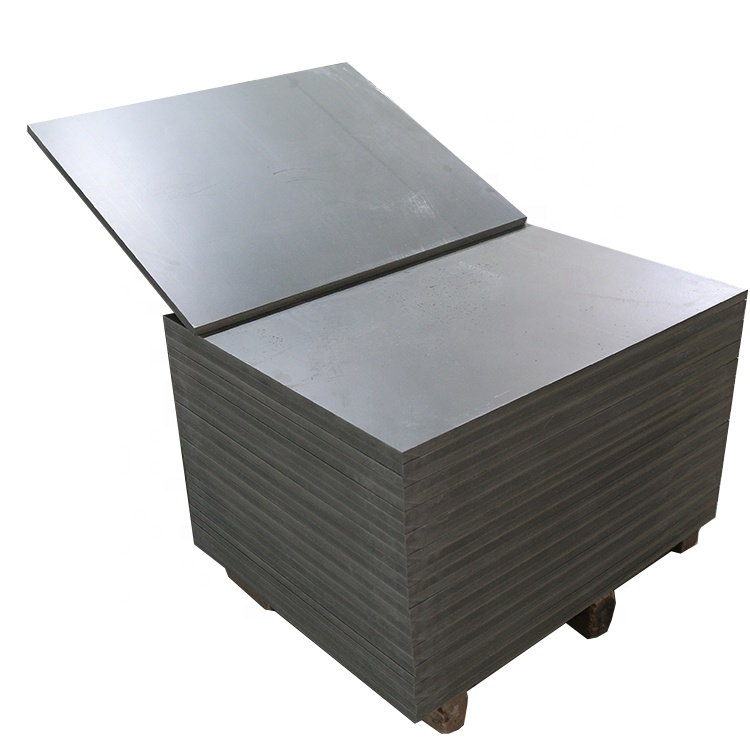

In the workshop, the delegation's first stop was the dedicated production line for Steel Pallets for Block Machines. The clients closely observed the entire process, from laser cutting of high-strength steel plates and precision bending to robotic welding and stress-relief heat treatment. Our engineers detailed the steel selection criteria, explaining why specific grades of wear-resistant steel plates are better suited to withstand the potential abrasion challenges posed by local sand and gravel raw materials in Tanzania. The clients paid particular attention to the consistency of welding techniques and the non-destructive testing of welds, requesting relevant quality inspection reports for verification.

Subsequently, the delegation moved to the assembly and testing area for Heavy Duty Block Pallets. These products are specifically designed for high-intensity, continuous production operations. We conducted a live demonstration of a fatigue test simulating extreme load conditions: subjecting the pallets to cyclic impact loads far exceeding conventional standards. Real-time data showed that even under苛刻 conditions, the main structure of the pallets remained intact, with no plastic deformation or cracking. The client's Technical Director personally inspected the post-test samples, approving their impact resistance and structural redundancy design, and noted that this highly aligns with the requirements of their upcoming 24-hour production line following factory expansion.

2. Deepening Technical Dialogue: Discussions on Compatibility and Scenario-Specific Solutions

During the subsequent technical seminar, the focus shifted to product adaptability and scenario-specific applications. The clients provided documentation on their existing and planned brick machine models, leading to discussions on balancing standardization and customization for Brick Making Machine Pallets. We presented our modular design database, illustrating how a basic pallet platform can be quickly adapted to multiple brands and models of brick machines by adjusting parameters such as mounting hole positions and frame height. This approach ensures production economy while meeting clients' individual needs.

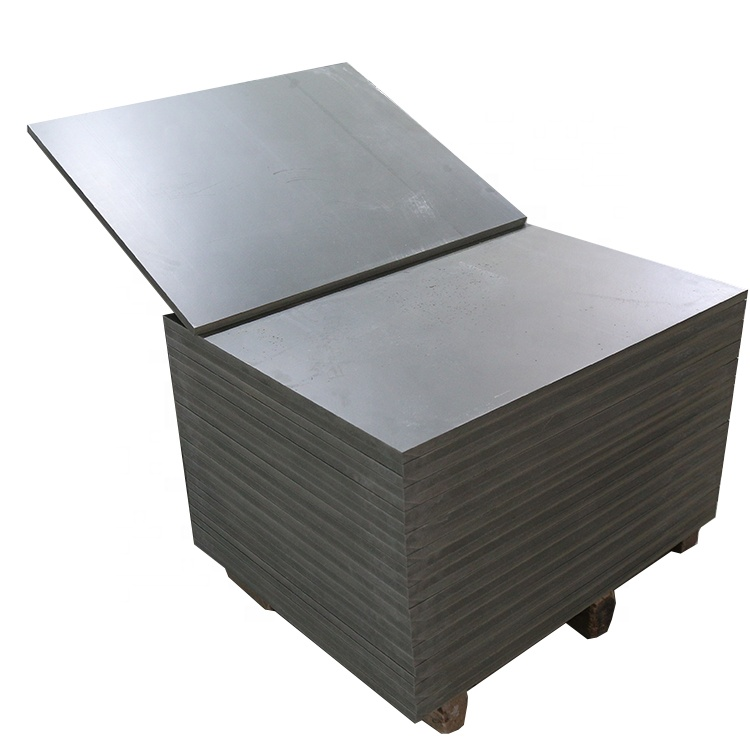

Addressing the diverse needs of the Tanzanian market for producing solid bricks, hollow blocks, and paving stones, the meeting delved into the technical details of Concrete Block Pallets. The clients were particularly concerned about concrete adhesion and mold cleaning efficiency. Our technical team presented samples treated with the latest nano-coating surface technology, which significantly reduces the adhesion of concrete slurry, ensures a clean surface after demolding, and minimizes downtime for cleaning. We also provided comparative data on how different surface textures (smooth, fine-grained, coarse-grained) of pallets affect the surface finish of blocks, helping clients make optimal choices based on their end-product positioning.

3. Performance Testing and Quality System Review

To provide the most direct product experience, we arranged live production testing in our trial operation area. Using the cement and aggregate formulas provided by the clients, test production was conducted on our experimental brick machines equipped with different Block Machine Pallets. The clients supervised the entire process of block forming, curing, and demolding, focusing on evaluating the pallets' performance under actual vibration and compaction conditions, as well as the edge integrity and dimensional accuracy of the blocks after demolding. The test results fully met, and in some cases exceeded, the clients' internal control standards.

Furthermore, the delegation thoroughly reviewed our quality management system documents, including raw material inspection records, key process control point (CPK) data, finished product inspection standards, and traceability systems. The clients commended our practice of including durability testing for Heavy Duty Block Pallets as part of the routine factory inspection, viewing it as a demonstration of responsibility for the product lifecycle.

4. Reaching Consensus and Prospects for Future Cooperation

After intensive inspection, testing, and discussions, the Tanzanian client delegation provided positive feedback in the concluding meeting. They stated that this factory audit not only comprehensively verified the excellent performance and reliability of our Block Machine Pallet series but also demonstrated our robust manufacturing and quality assurance capabilities. Both sides reached preliminary intent for cooperation and agreed on the next steps, including sample verification and market development planning. This visit successfully established a channel of mutual trust and technical dialogue, paving the way for in-depth collaboration in the Tanzanian and broader East African markets. We believe that through continuous product innovation and quality commitment, we will become a reliable partner supporting the development of Tanzania's construction indust