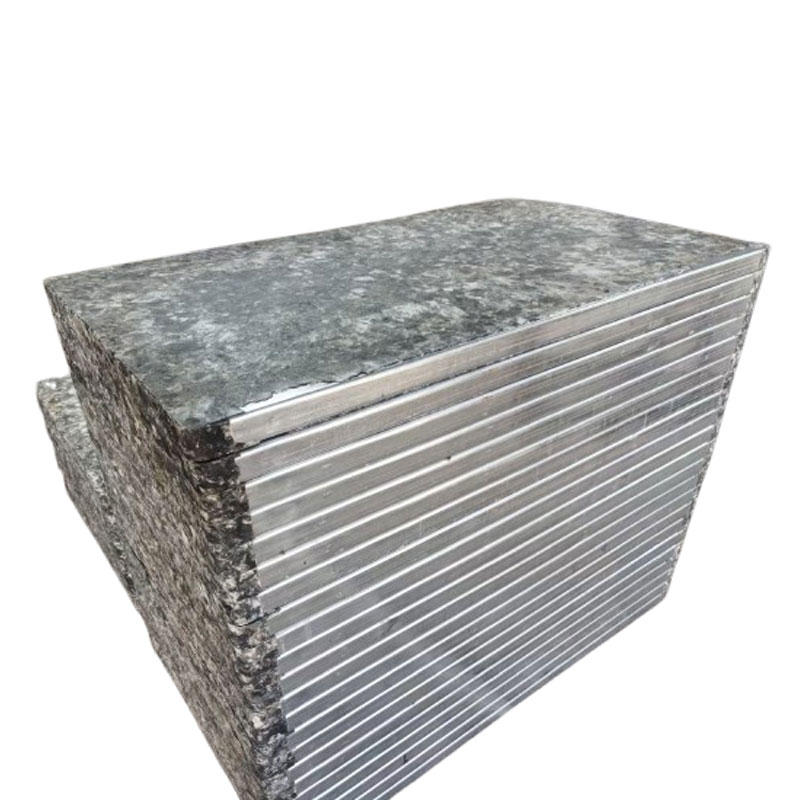

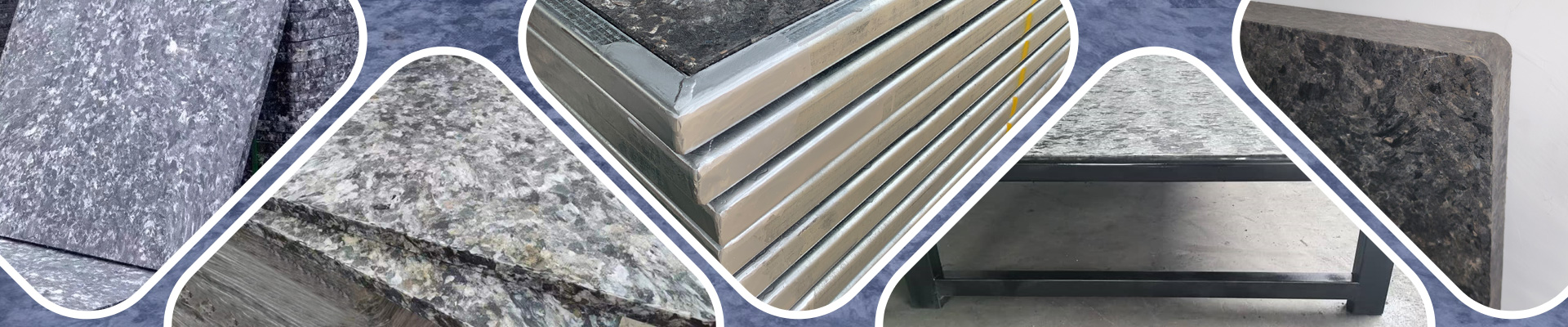

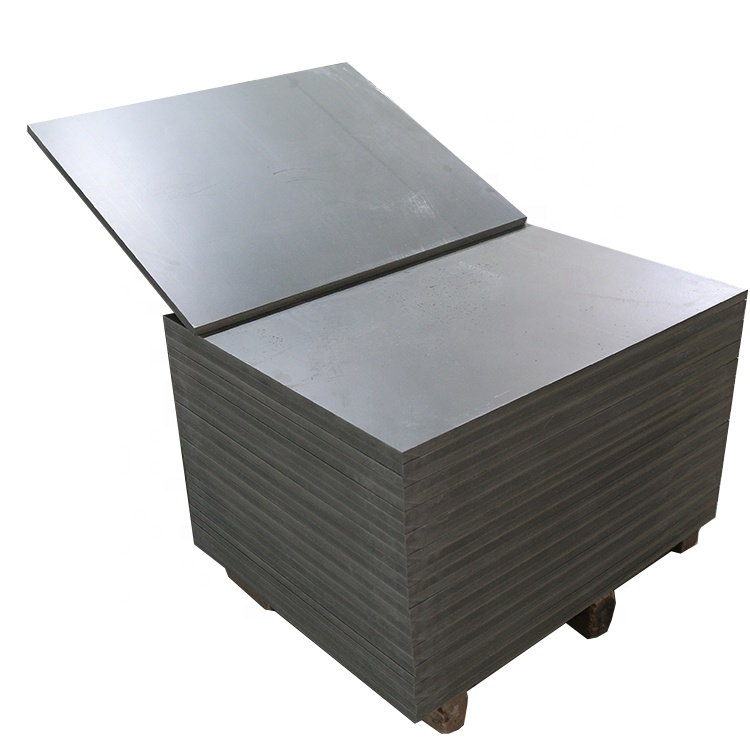

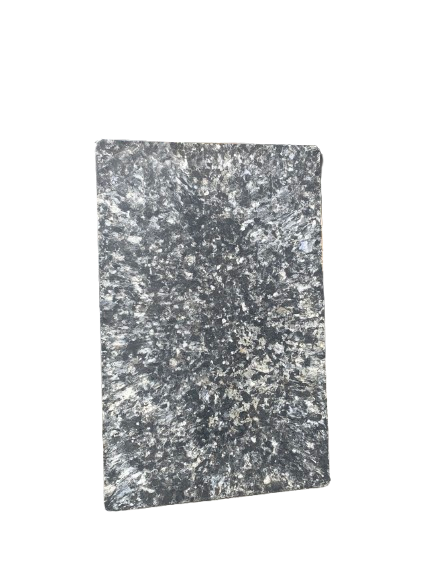

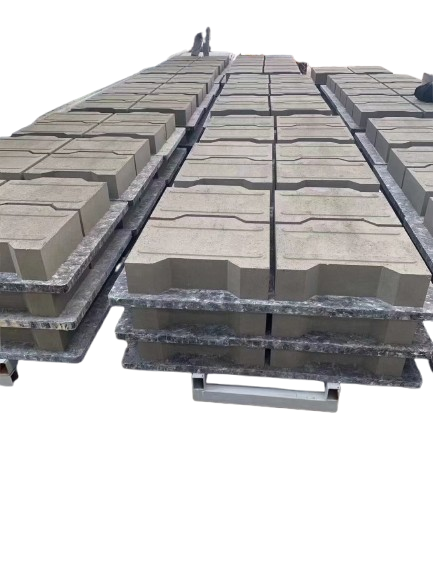

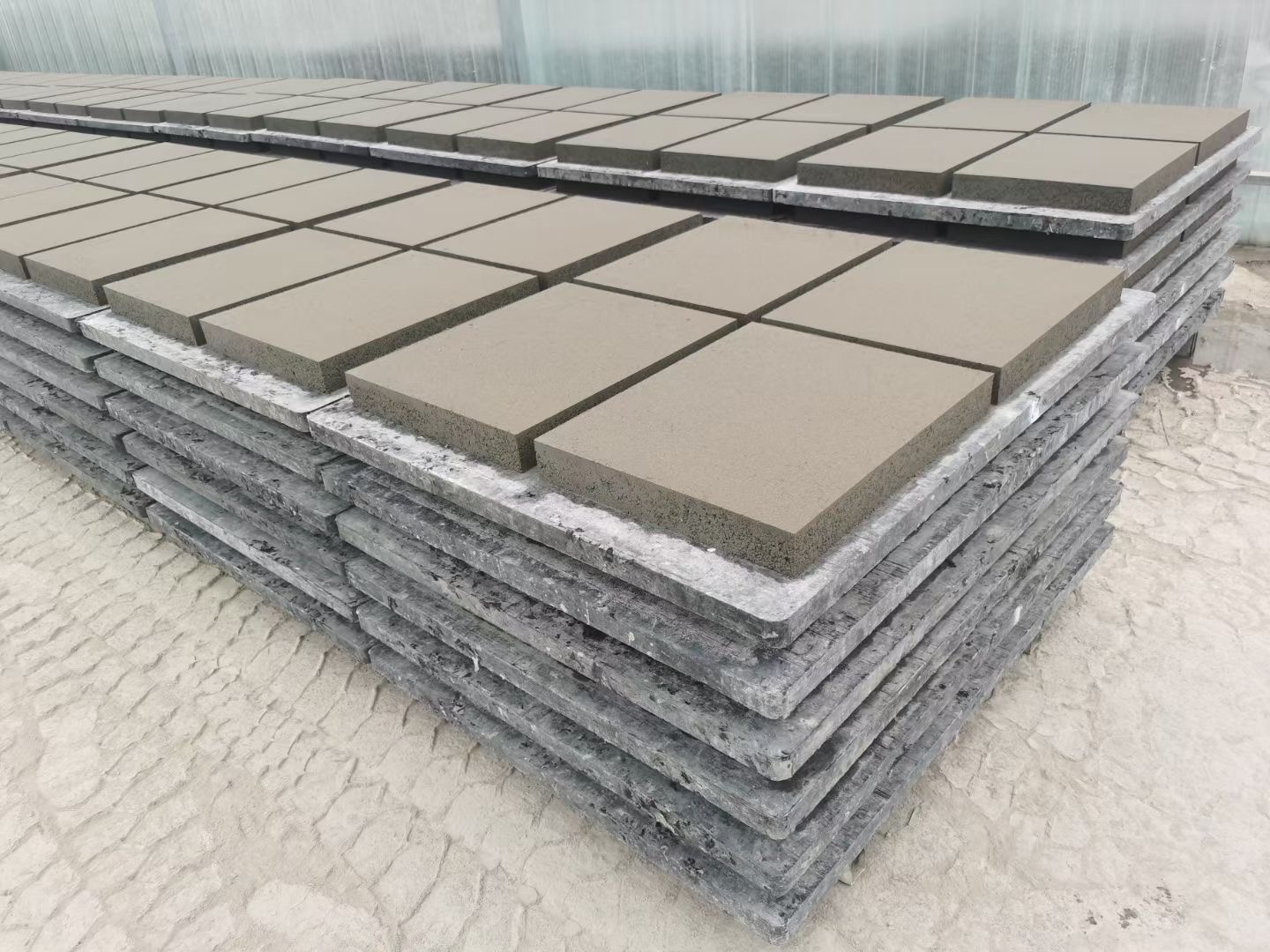

Fiberglass GMT Pallet with Steel EdgeBlock machine pallet Strong alliance, specially designed for heavy-duty use: Made of glass fiber felt reinforced thermoplastic (GMT) and equipped with tin plated steel edges, the toughness of glass fiber is perfectly combined with the wear-resistant protection of steel, specially designed for high load brick factories with ultra-high strength and ultra long service life requirements for pallets.

Durability upgrade and reduced wear and tear: The unique steel edge design can significantly reduce edge cracking, surface wear, and corner damage of the pallet, greatly improving the pallet's resistance to wear and tear, reducing production interruptions and replacement costs caused by pallet damage, and adapting to high-intensity operations of heavy-duty block machines.

Flexible customization and wide adaptability: Steel edges can be added to the short or long sides of the pallet according to customer needs, with a high degree of customization; At the same time, it has strong adaptability and can be used to produce various types of bricks, meeting the production process and equipment needs of different brick factories, with practicality and flexibility.

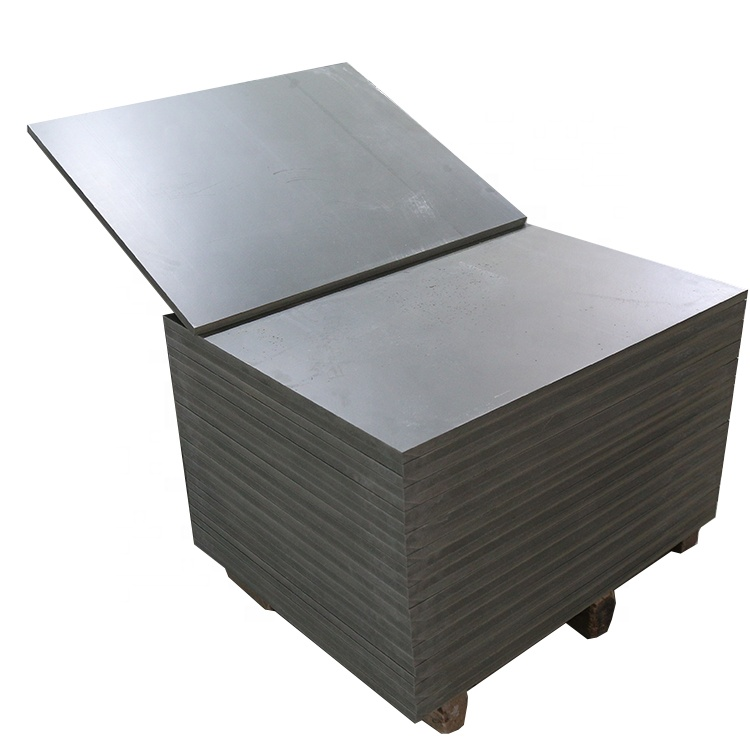

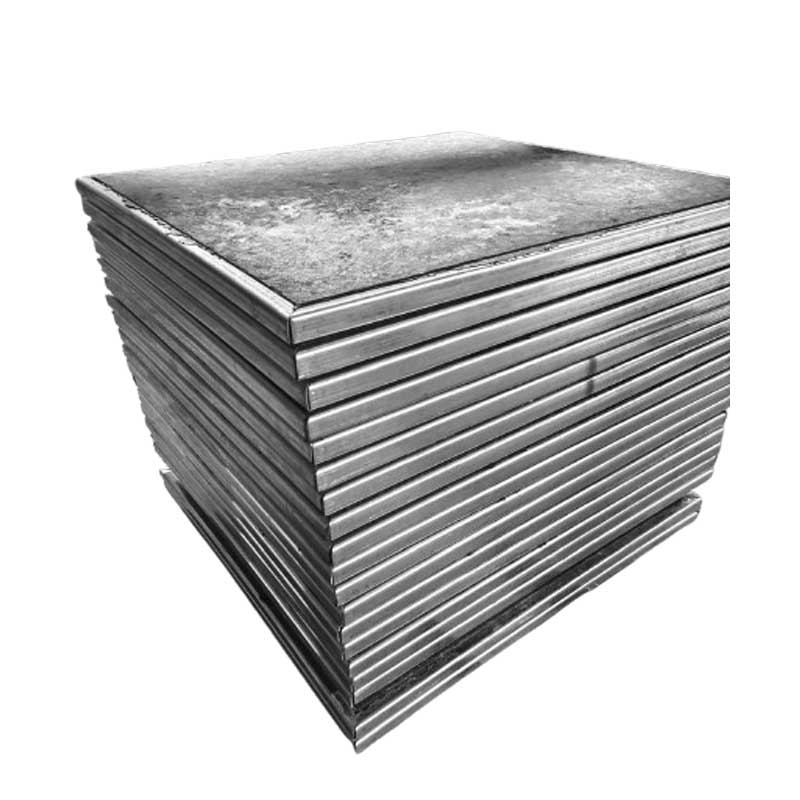

Fiberglass GMT Pallet with Steel EdgeFiberglass GMT PalletGMT Pallet With Steel EdgeBlock Machine palletEmailMore