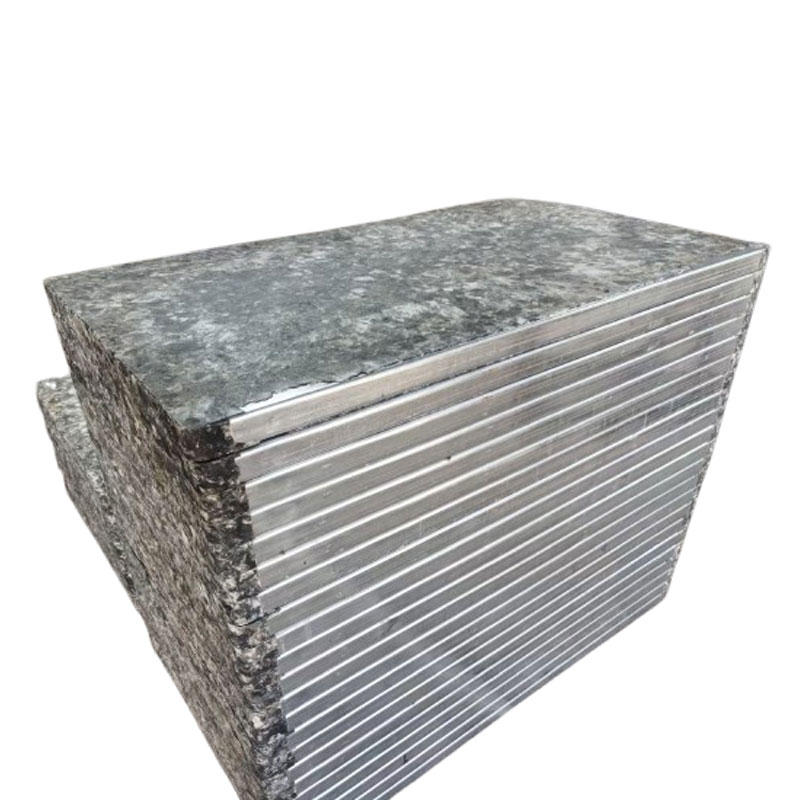

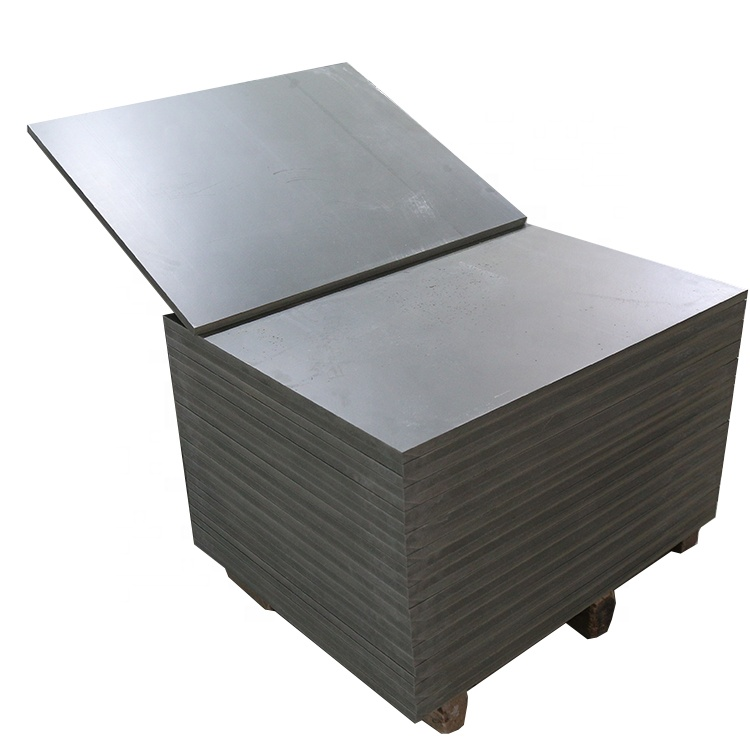

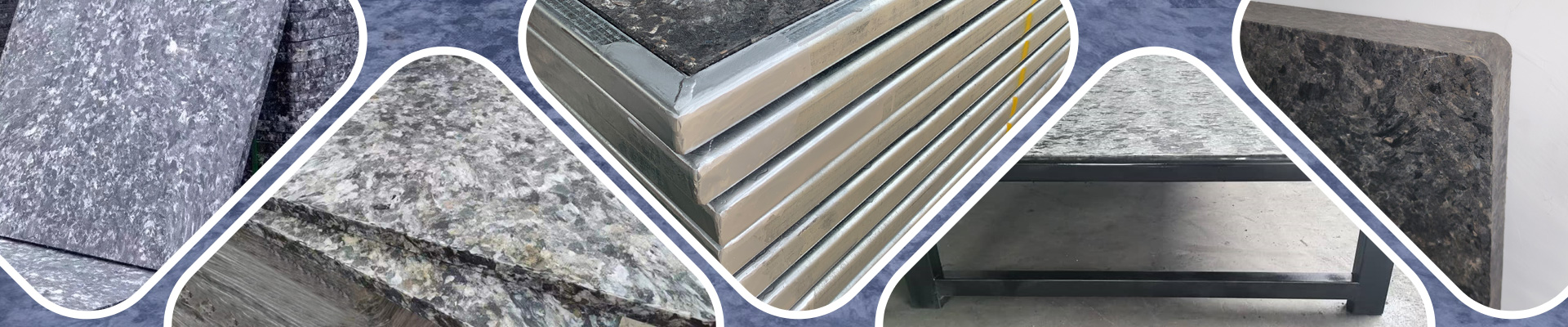

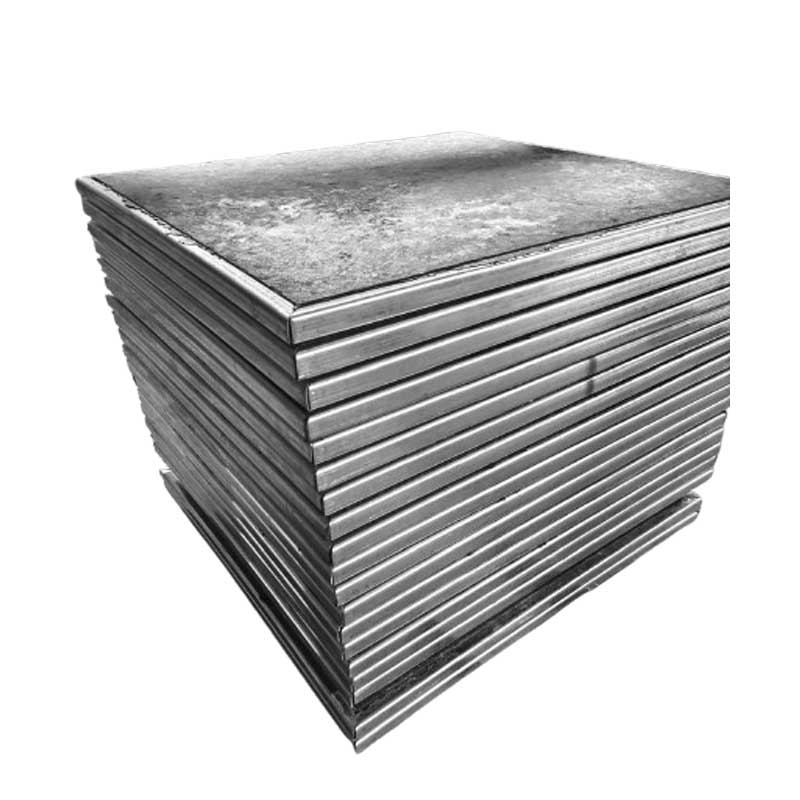

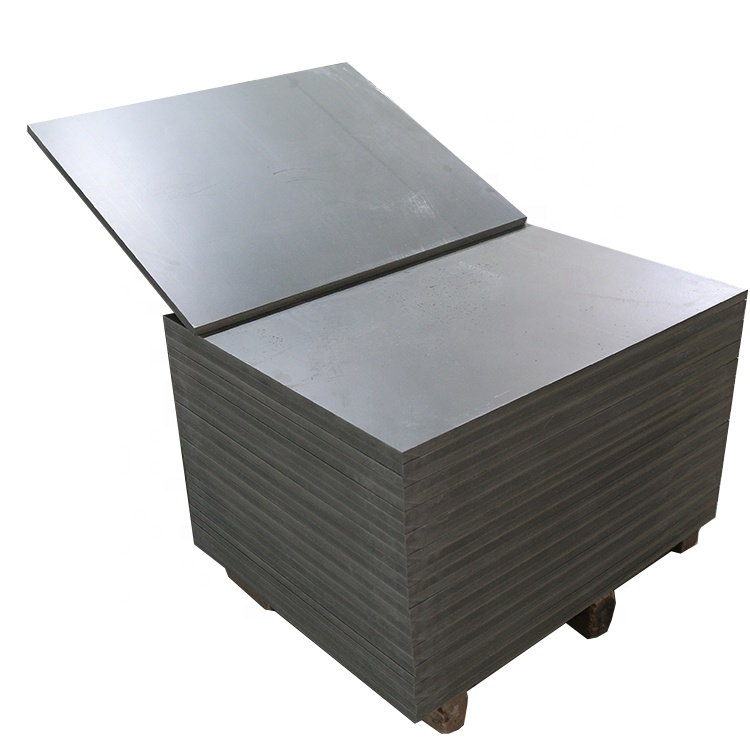

Four-Leg Steel Edge Reinforced Brick PalletThe edges are reinforced with steel plates and equipped with four reinforced support legs. The dual structure design greatly enhances the overall strength of the product, which can withstand high-intensity use scenarios such as collisions and load-bearing in brick factory production. It has durability far beyond ordinary pallets and reduces frequent replacement costs.

The design of four supporting legs not only ensures stability during stacking and avoids the risk of collapse, but also simplifies the transportation and storage process of bricks, achieving efficient operation without the need for additional auxiliary tools, adapting to the working rhythm of brick machines and brick production lines, and improving overall production efficiency.

Balancing high-quality products with competitive prices, meeting the demand for cost-effective pallets in markets such as the Middle East; At the same time, it has a wide range of applications and can be matched with various production scenarios such as hollow bricks, floor tiles, interlocking bricks, solid bricks, etc., without the need for separate adaptation for different brick types, reducing the investment cost of enterprise equipment.

Four-Leg Steel Edge Reinforced Brick PalletReinforced Brick PalletBrick PalletEmailMore