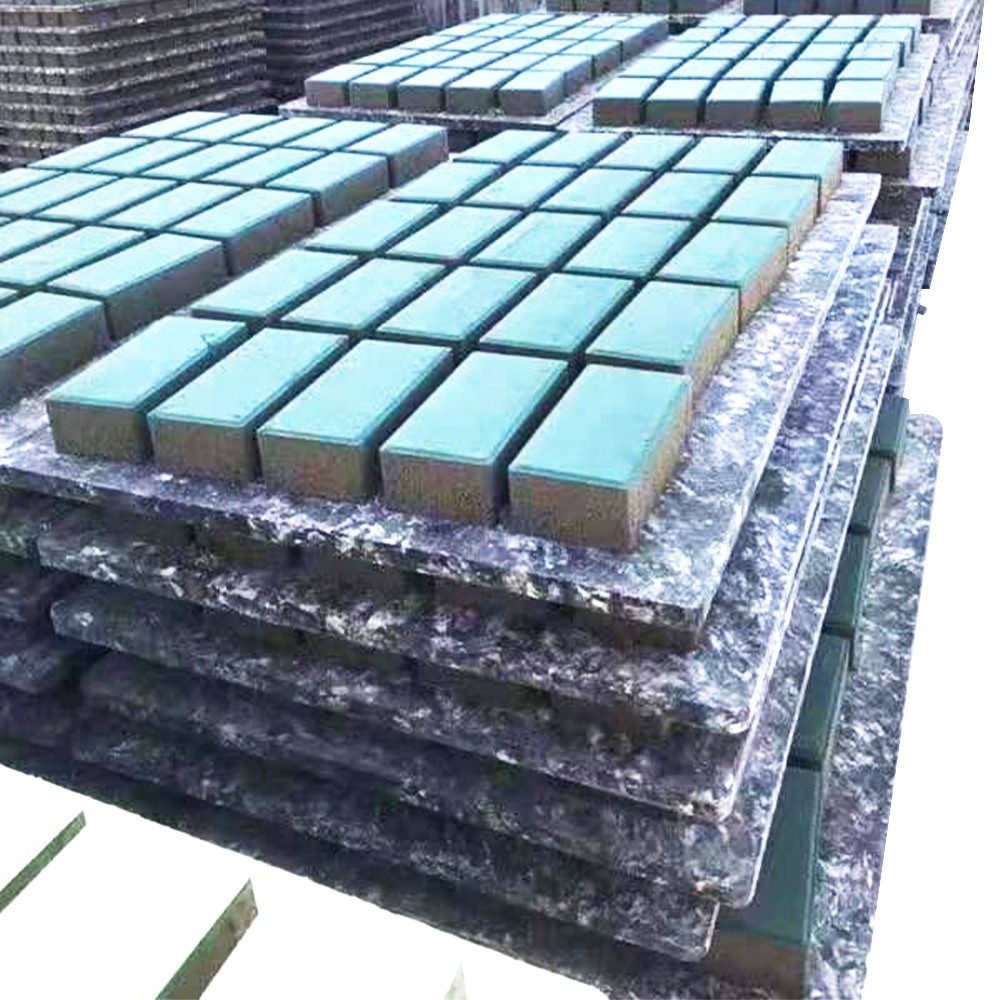

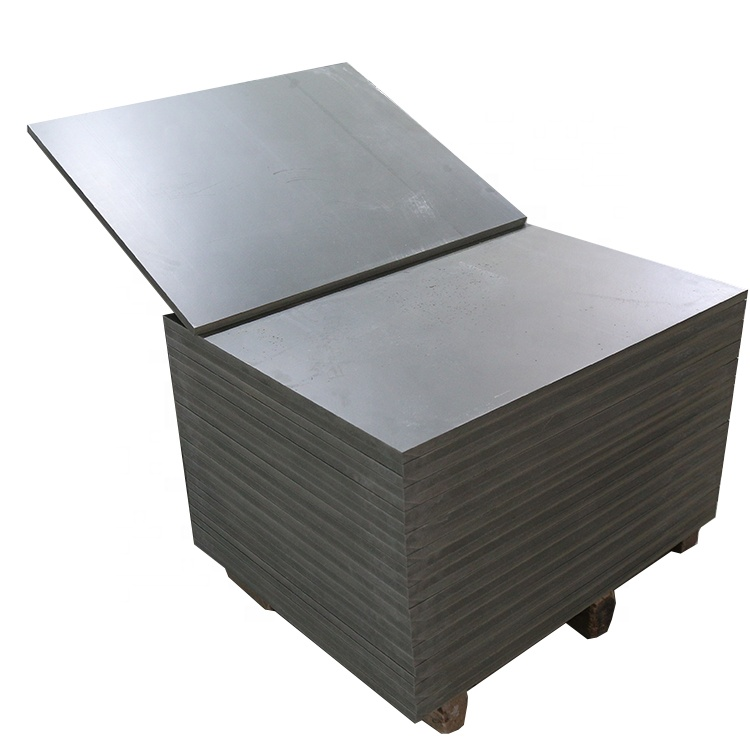

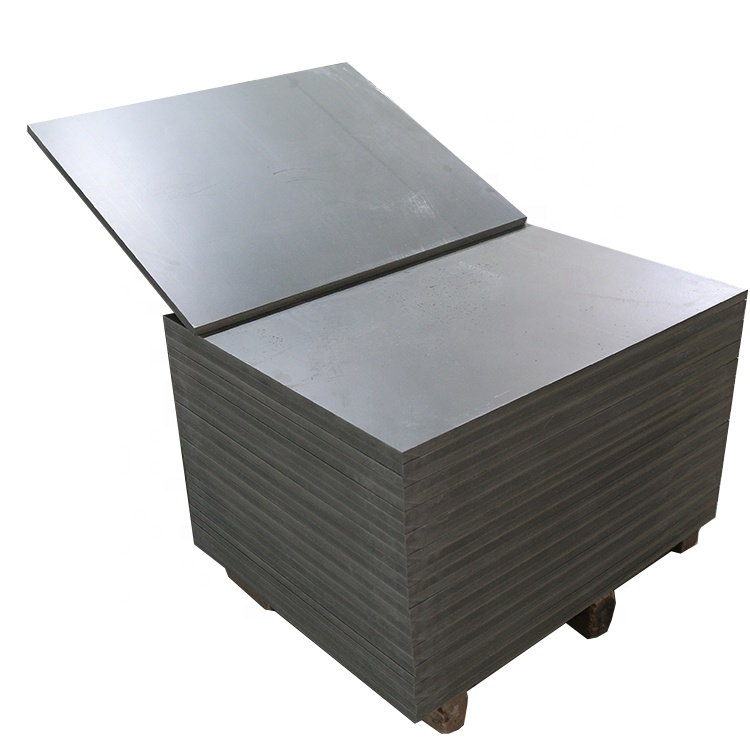

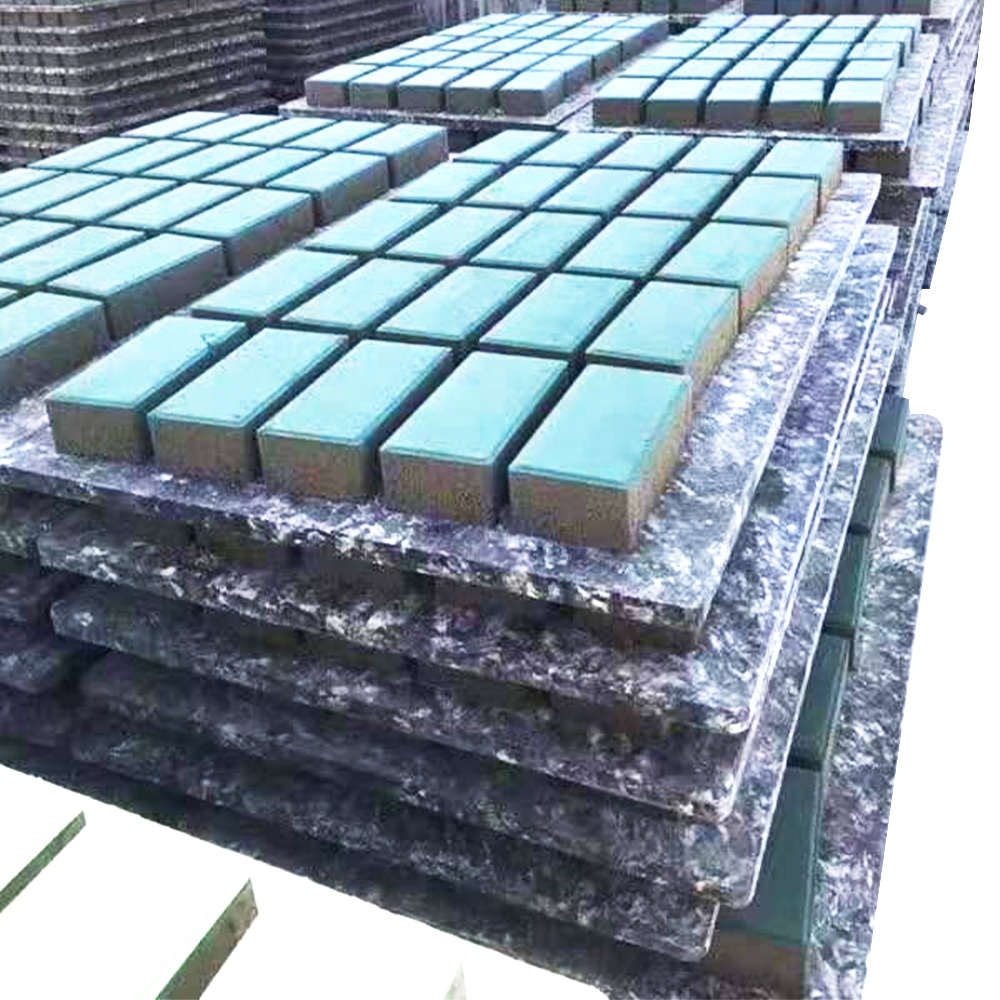

Our Concrete Block Pallet made with 50% black glass fiber is designed for block factories that require higher strength, longer service life, and stable performance in daily production.

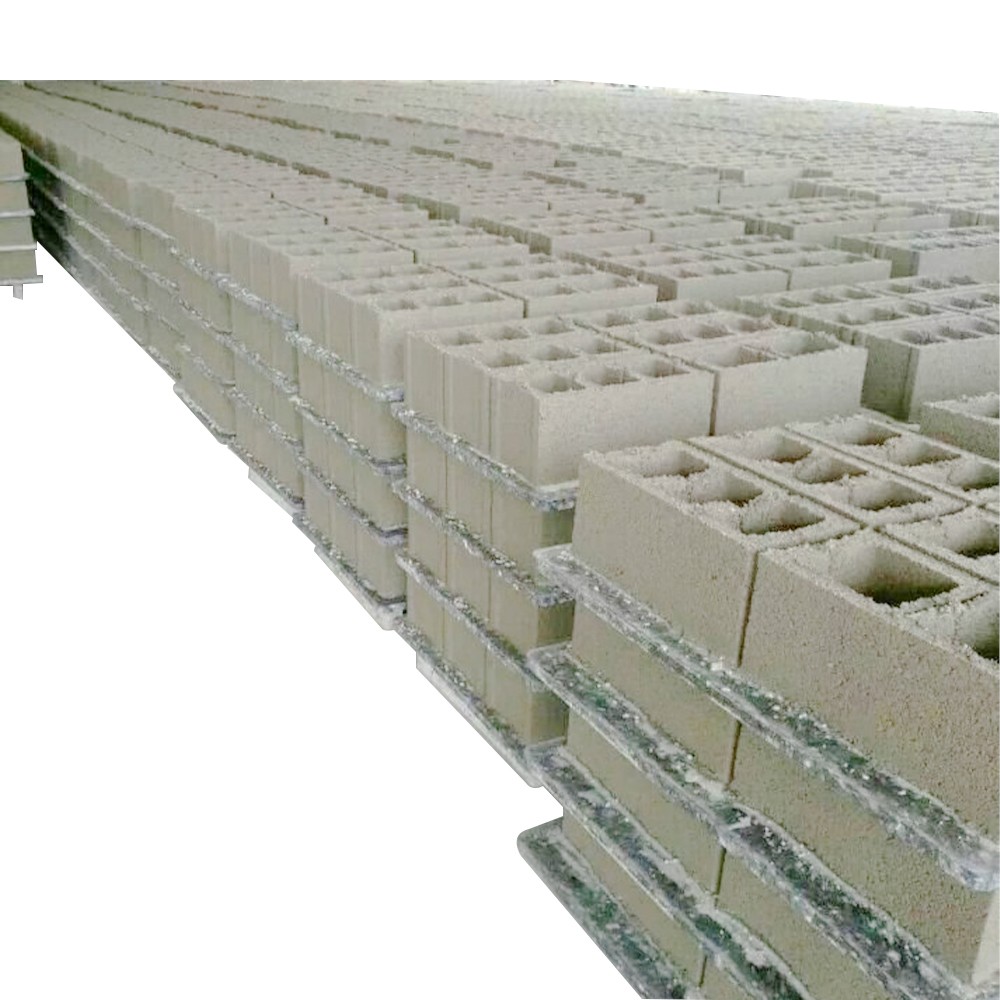

This Glass Fiber Pallet is widely used as a Block Machine Pallet for producing solid blocks, hollow blocks, and especially heavy products such as curb stones. Compared with standard pallets, this Heavy Duty Block Pallet offers better hardness and edge protection, reducing pallet damage during long-term operation.

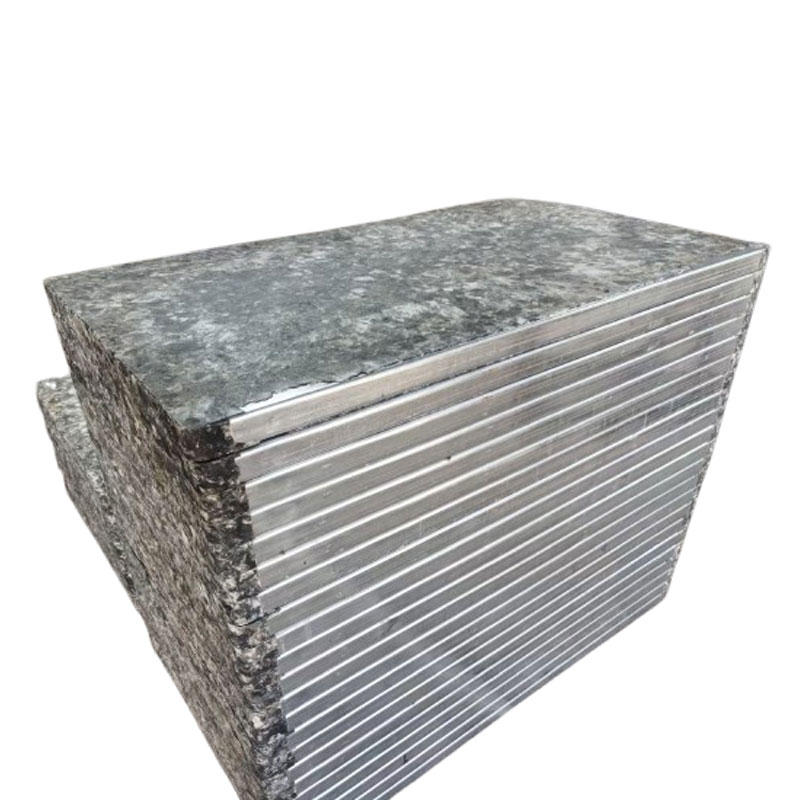

Extended Service Life – Up to 12 Years

The reinforced structure of this Concrete Block Pallet protects the pallet edges from cracking and impact damage. With proper use, the service life can reach up to 12 years, significantly reducing replacement frequency.

For factory owners, choosing a durable Fiber Pallet for Block Machine means lower cost per year and more stable production planning.

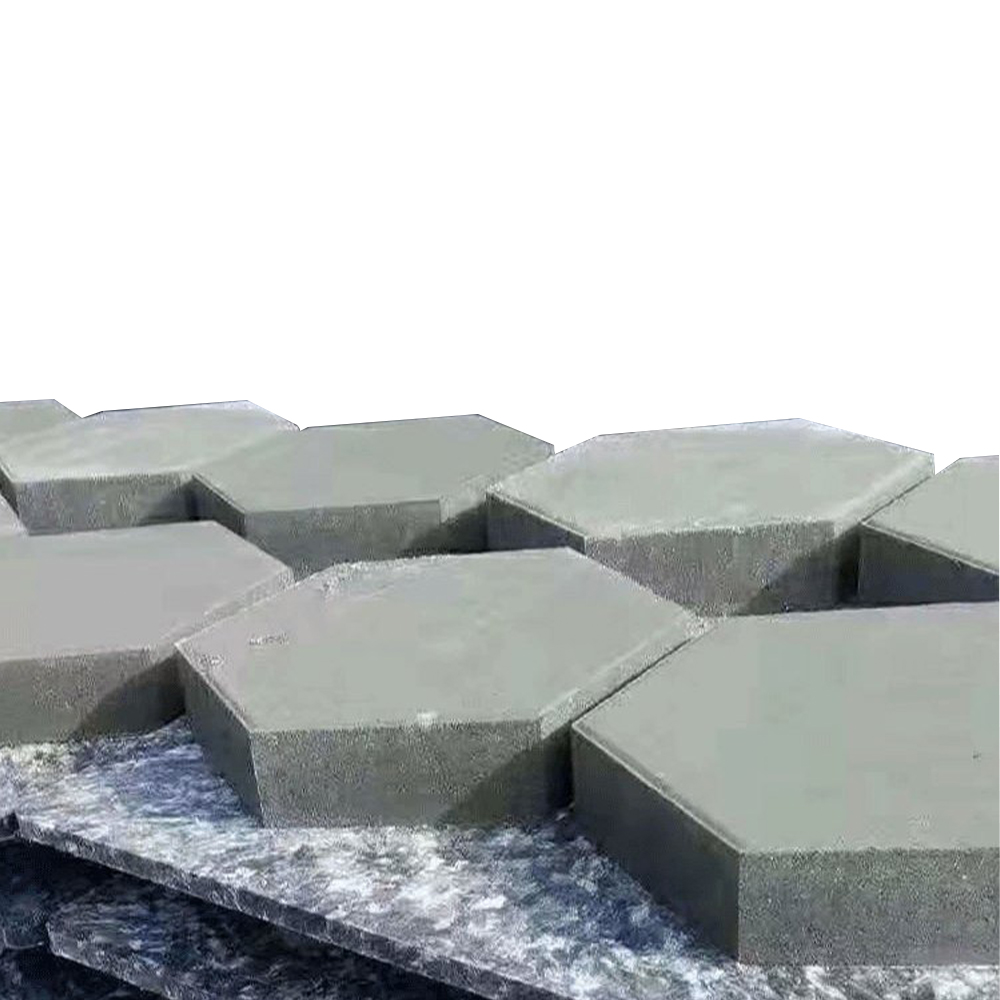

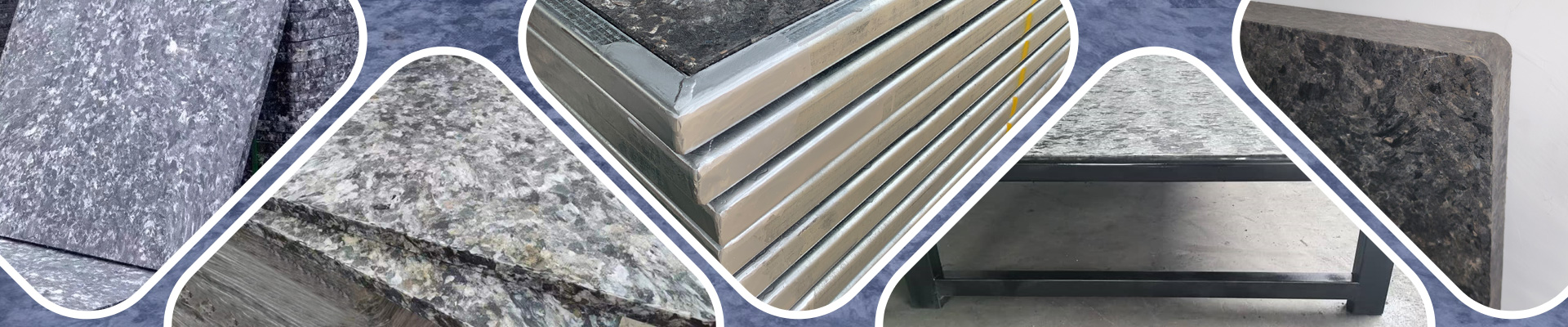

Higher Hardness for Heavy Concrete Products

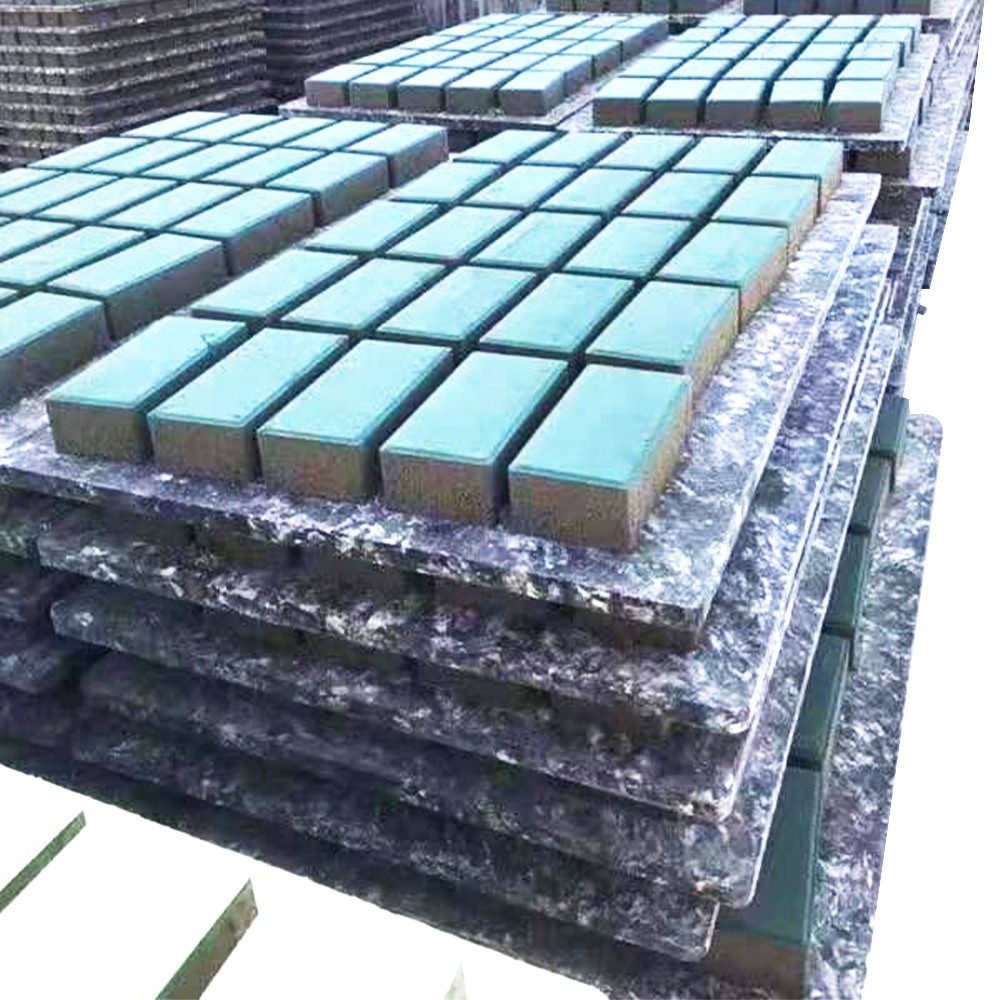

Thanks to the 50% glass fiber composition, this Glass Fiber Pallet provides higher rigidity and load-bearing capacity. It performs especially well when producing curb stones and other heavy concrete blocks.

As a Heavy Duty Block Pallet, it maintains flatness under pressure, ensuring consistent block dimensions and reducing defects caused by pallet deformation.

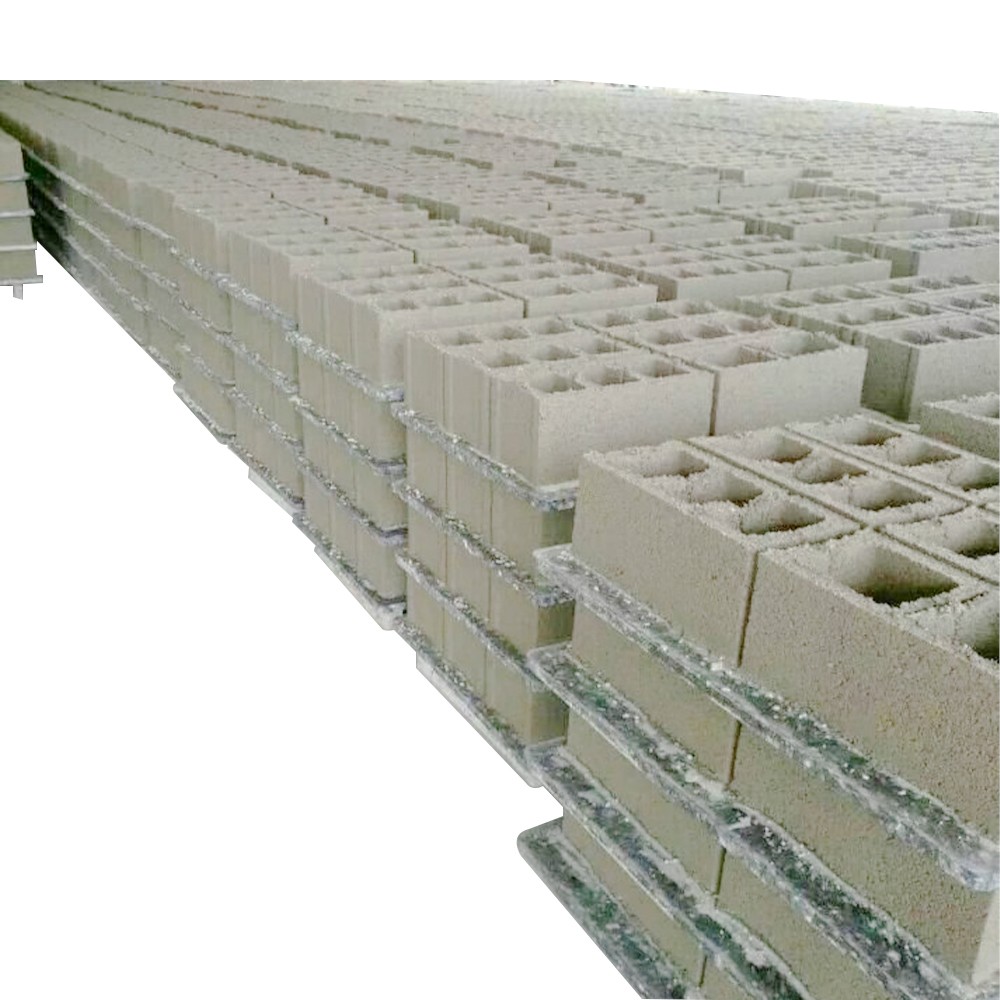

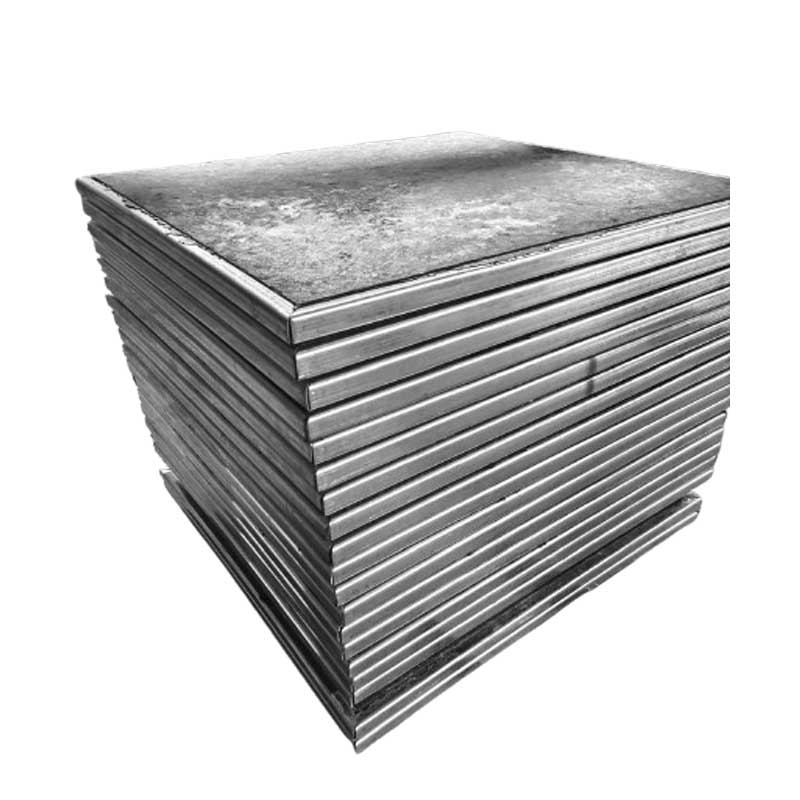

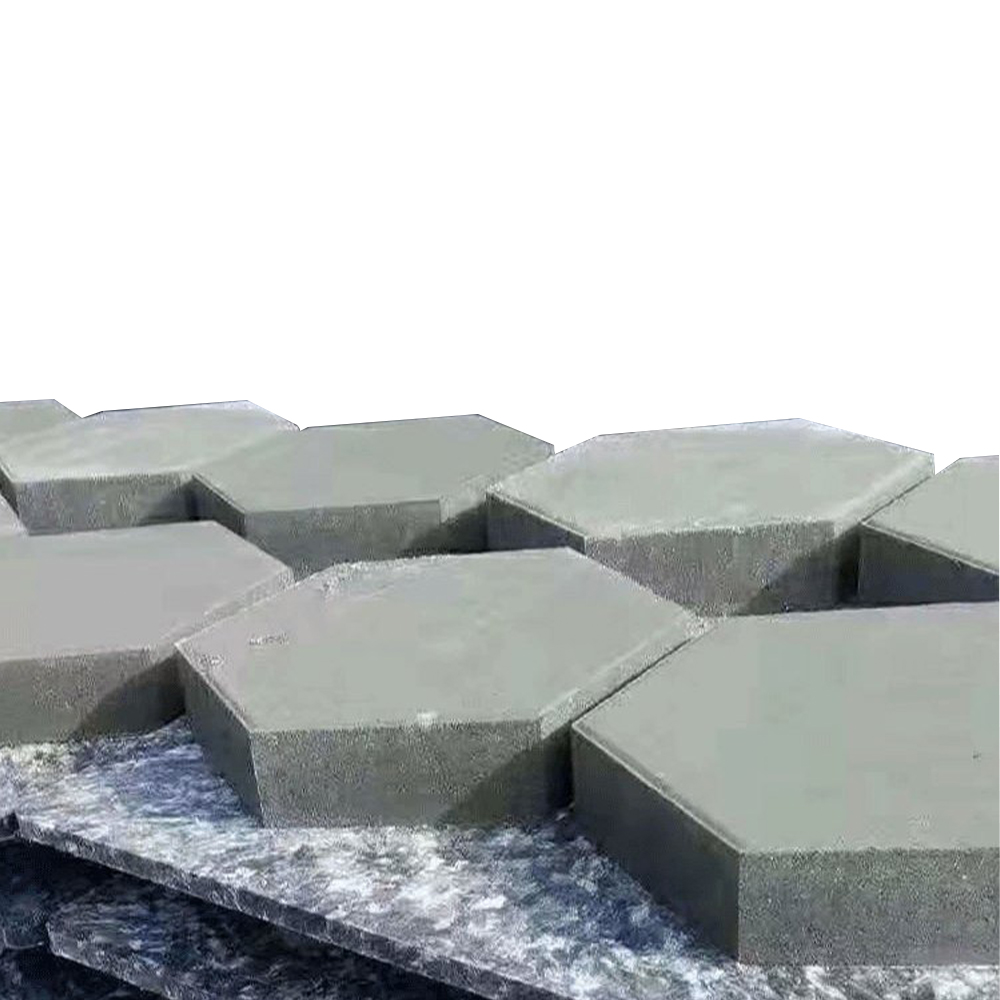

Suitable for Curing Room Use

This Concrete Block Pallet is suitable for curing room environments, including high humidity and temperature changes. The material structure ensures stable performance without warping or delamination.

Many customers choose this Block Machine Pallet specifically for curing room use, where pallet stability directly affects block quality and production efficiency.

Safe Design for Smooth Operation

Our new structural design avoids edge jamming and handling issues commonly found in traditional reinforced pallets. This makes the Fiber Pallet for Block Machine safer during pallet circulation, stacking, and curing room transfer.

The improved safety design helps reduce unexpected downtime and improves overall factory operation efficiency.