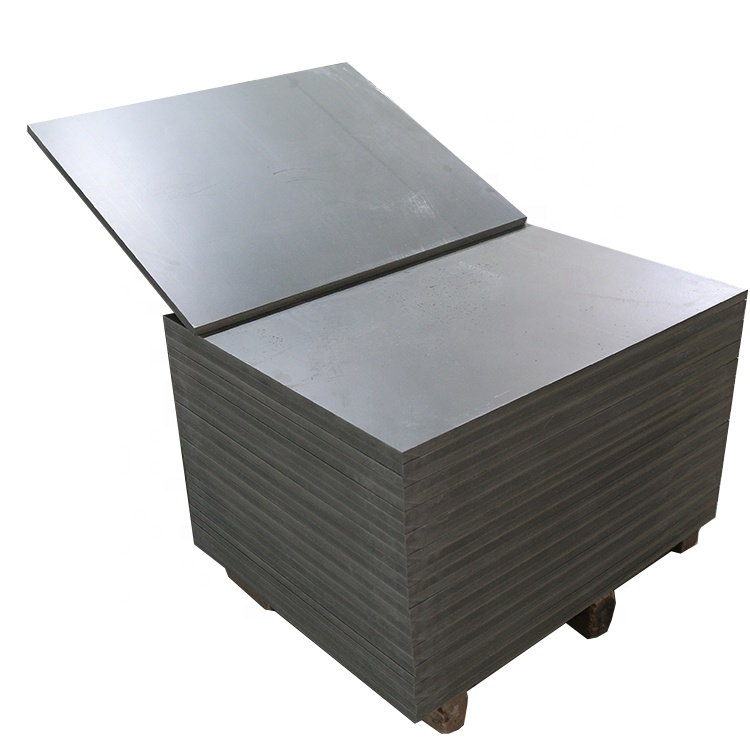

In the global brick and block manufacturing industry, the choice of brick machine pallets is a critical decision that directly impacts your production efficiency, product quality, and overall profitability. While composite pallets for brick making have become the preferred choice over traditional wood, many buyers face confusion when selecting the right type.

The key differentiator lies in the glass fiber content. As a leading manufacturer and exporter specializing in high-performance brick making pallets, we are here to demystify the selection process. The best brick machine pallet isn't always the one with the highest fiber content; it's the one that perfectly matches your specific operation.

Understanding Glass Fiber Content in Our Brick Pallets

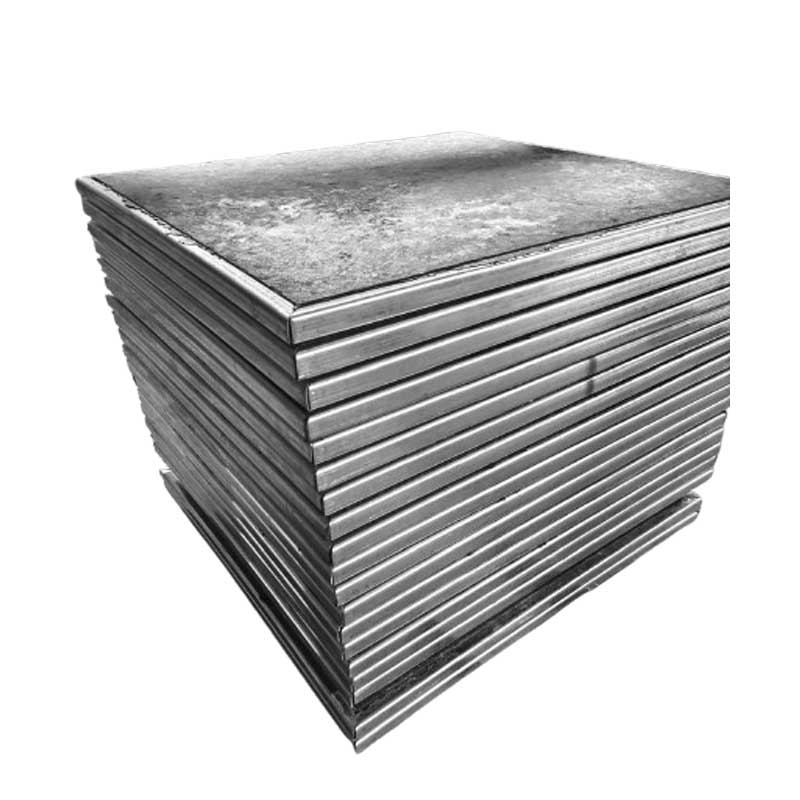

Our industrial brick pallets are engineered with precise glass fiber ratios: 30%, 50%, 70%, and 85%. This content is the backbone of the pallet, determining its:

Load-Bearing Capacity

Hardness & Impact Resistance

Longevity & Durability

Moisture & Chemical Resistance

Your 4-Step Guide to the Perfect Brick Machine Pallet

Follow this practical guide to identify the ideal composite brick pallet for your factory.

1. Select by Pallet Size

Small Size Pallets: We recommend our 30% Glass Fiber Brick Pallet. It offers exceptional value, provides sufficient support, and can deliver a service life exceeding 6 years.

Large & Extra-Large Pallets: For these heavy-duty brick pallets, a minimum of 50% Glass Fiber is essential. Higher fiber content prevents bending and ensures structural integrity over a larger span.

2. Select by Brick Machine Type

Mechanical Brick Machines: The 30% GMT pallet is a cost-effective and fully capable choice for these machines.

Semi-Automatic Machines: Opt for the balanced performance of our 50% Glass Fiber brick machine pallet to meet higher demands for durability.

Fully Automatic Hydraulic Presses: These high-speed machines require superior pallets for brick making. We recommend 70% and above content for maximum hardness and shock resistance, minimizing production downtime.

3. Select by Brick Type

Hollow Blocks & Standard Concrete Bricks: Our 30% to 50% fiber content brick pallets are perfectly suited for these common products.

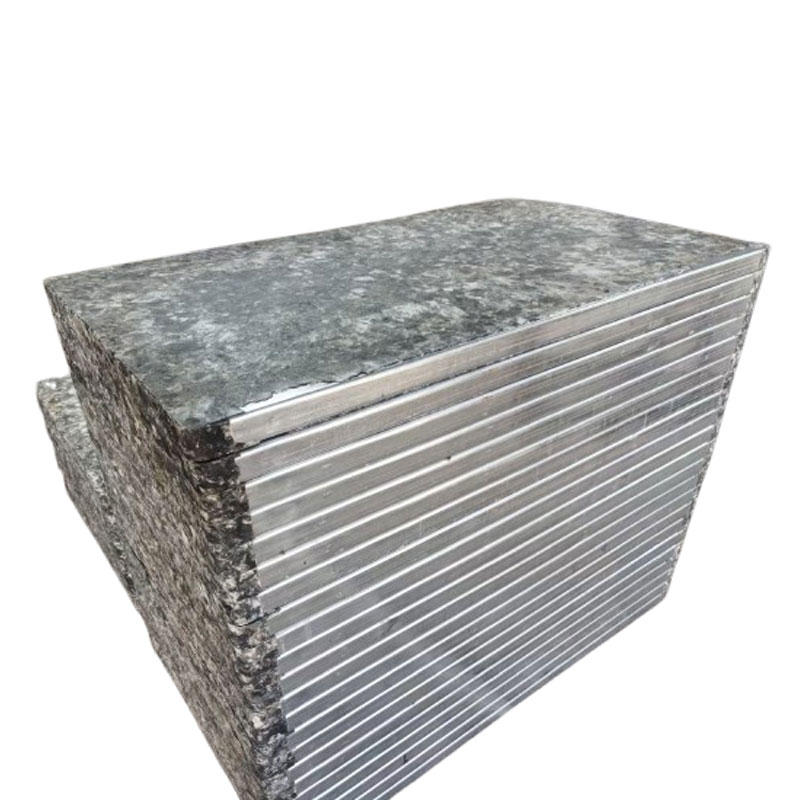

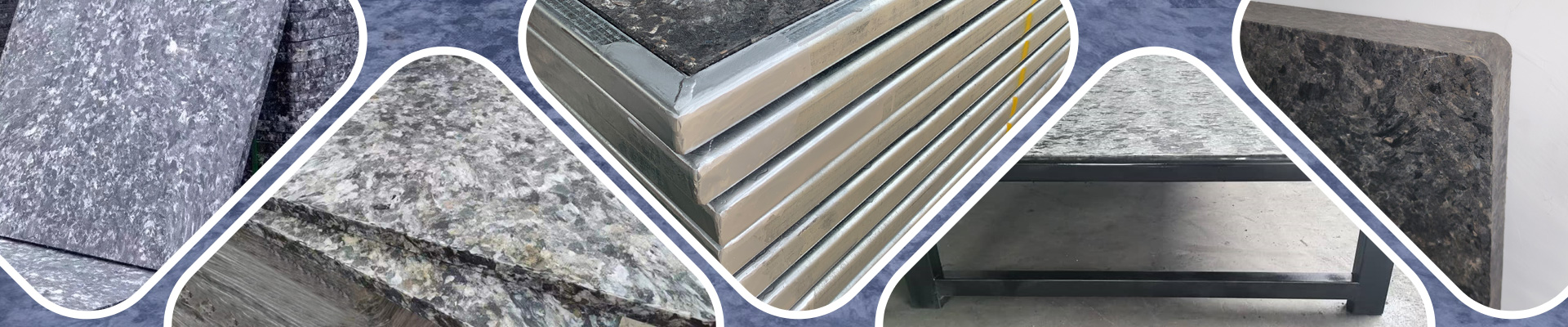

Curbsstones & Heavy Paving Blocks: For these demanding applications, choose a pallet with a minimum of 50% fiber content AND reinforced steel edges. This combination is crucial to prevent pallet flexure, which can cause product breakage.

4. Select by Usage Environment

Standard Storage Conditions: The guidelines above apply directly.

High-Temperature Curing Rooms: If your brick machine pallets frequently enter high-heat curing chambers, steel edge reinforcement is mandatory. Pair this with at least a 50% fiber pallet to combat warping and dramatically extend service life.

Why Choose Our Composite Brick Pallets?

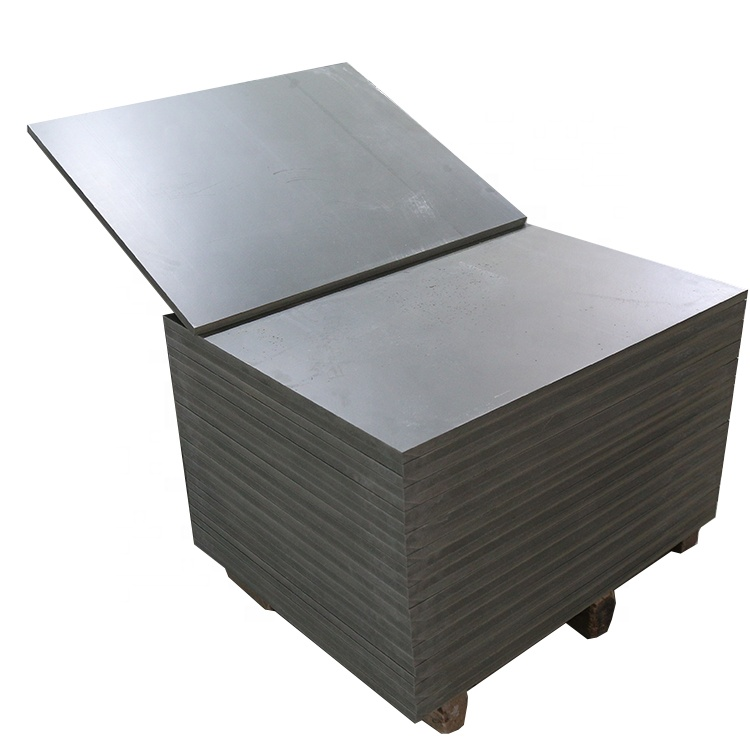

Long-Lasting Durability: Outperform and outlast wooden and plastic alternatives.

Optimized Cost-Per-Use: The right brick pallet reduces long-term operating costs.

Superior Brick Quality: A flat, stable surface ensures perfect brick bottom finish.

Global Export Standards: Our pallets for brick making are built to withstand rigorous international shipping and use.

Still Unsure Which Block Machine Pallet is Right for You?

Contact our experts today! Provide your brick machine model, common pallet sizes, and primary brick types. We will provide a free, no-obligation consultation and can arrange for sample brick making pallets to be sent to your facility.

Find your perfect fit and boost your productivity with our high-quality brick pallets.