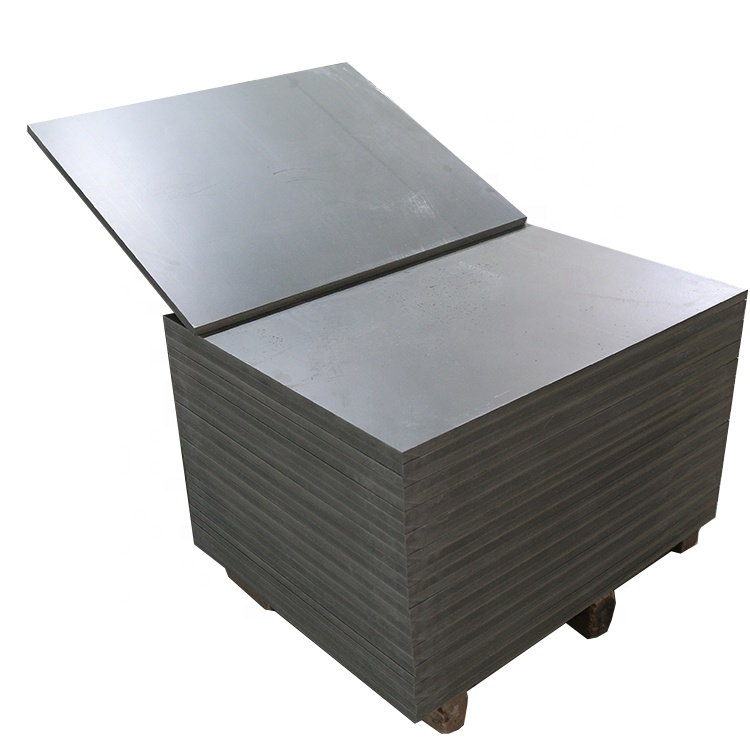

What is a fiberglass pallet?

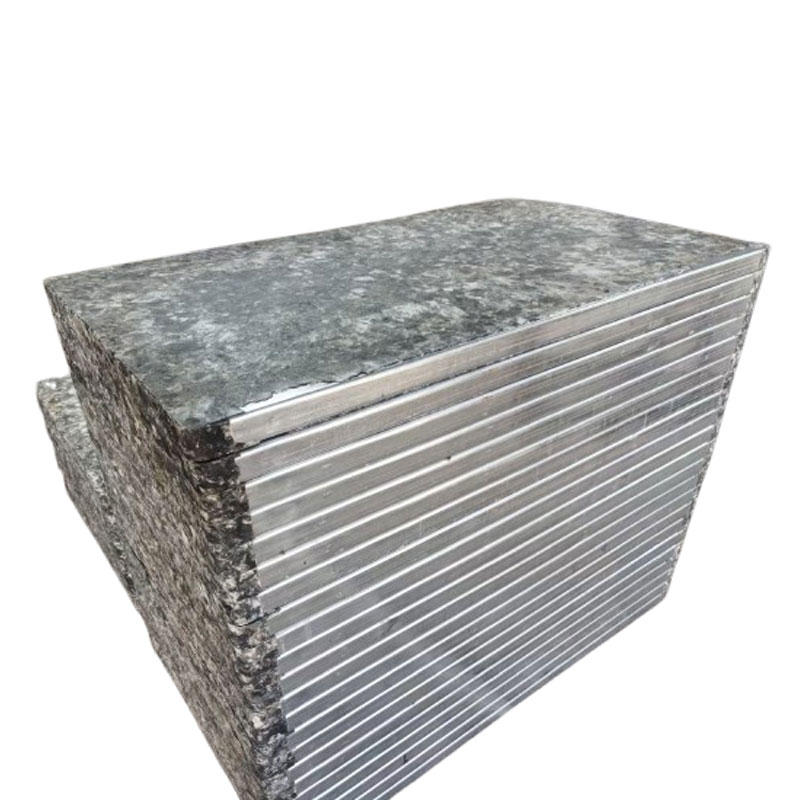

A fiberglass pallet is made of fiberglass, Hemp fiber, and PP (polypropylene). The fiber content can be adjusted according to the customer’s machine model and specific requirements. The higher the fiberglass content, the better the quality and durability, and accordingly, the higher the price.

How long does a fiberglass block machine pallet last?

A high-quality fiberglass block machine pallet can last 6–10 years, depending on the machine type and operating environment. For automatic brick machines, 70% fiberglass content is recommended for maximum durability and bending resistance.

Can GMT be used on all pallet for brick making machine?

Yes. GMT pallets are compatible with most automatic and semi-automatic block machines, such as ZENITH, Hess, QGM, QTY, QT series, and other models.

Custom thickness and size can be made to match your specific vibration platform.

What factors affect the block machine pallet price list?

The block machine pallet price depends on several key factors:

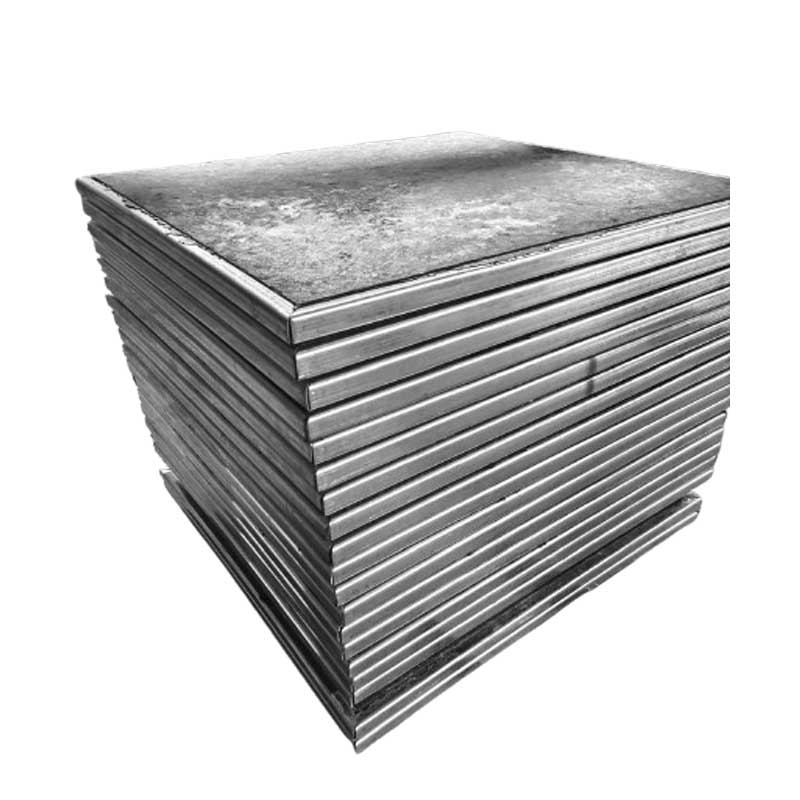

1.Material type – Fiberglass (GMT), PVC, steel, or bamboo pallets have different costs. Fiberglass GMT pallets are usually higher in price but offer longer lifespan and higher load capacity.

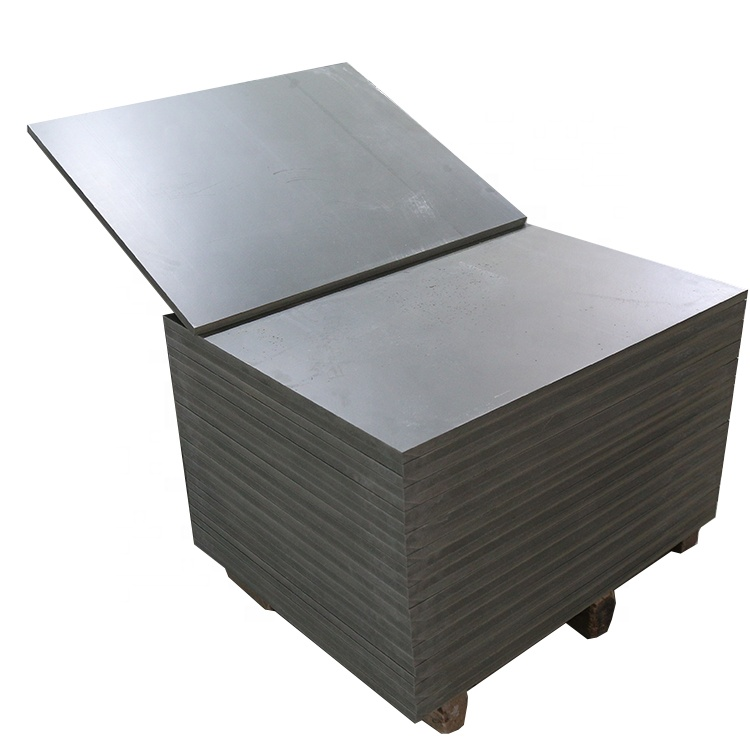

2.Size and thickness – Larger and thicker pallets (e.g., 1400×1300×35mm) cost more due to higher raw material usage.

3.Glass fiber content – A higher percentage (like 70%) increases both strength and cost.

4.Order quantity – Bulk orders often get a lower fiberglass brick pallet cost per piece.

5.Shipping terms – FOB, CIF, or DDP prices differ depending on freight and import charges.

What Is the Pallet Used for Block Production?

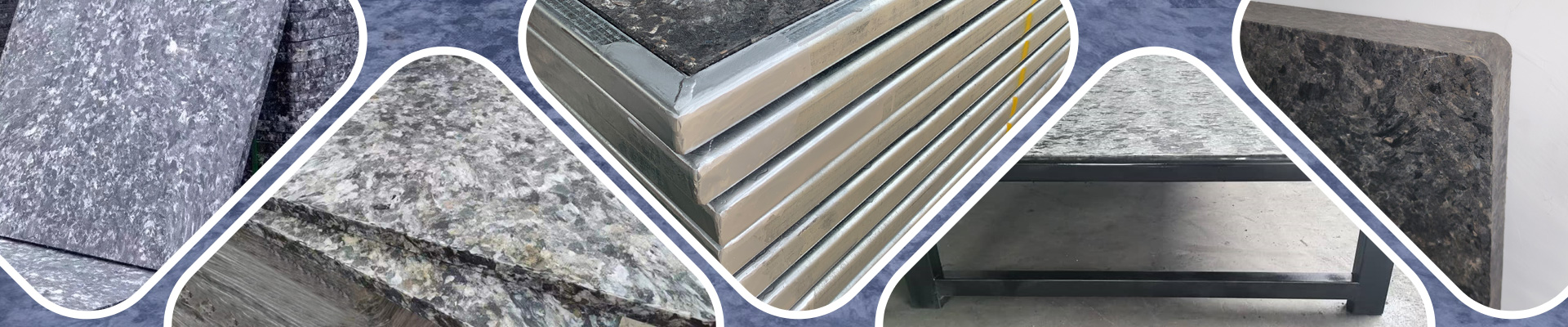

In concrete block production, the pallet — also known as the Concrete block machine pallet or Brick machine pallet — is a key part of the block forming process. It serves as the base platform that supports the fresh concrete blocks during vibration, molding, demolding, and curing.

When operating block machines such as the QT4-24, QT6-15, or QT10-15, the pallet carries the wet concrete mixture while the machine vibrates and presses the material into the desired block shape. After demolding, the blocks remain on the pallet, which is then transferred to the curing area. Once the curing process is finished, the pallet returns to the machine for the next production cycle.

The quality of the GMT Pallet or Fiberglass pallet directly affects production efficiency. Flat, strong pallets keep blocks even and prevent cracking. They also reduce downtime, improve block surface quality, and extend the lifespan of your machine line.

Factories in Africa, the Middle East, and South America prefer Fiberglass pallets because they offer the best combination of strength, durability, and long service life (6–10 years). Unlike wooden or steel pallets, the GMT Pallet is lightweight, easy to handle, and cost-effective — making it the ideal choice for modern automatic block production lines.

What are the advantages of block machine pallets?

Fiberglass pallets are stronger, more durable, and more resistant to moisture and deformation compared to wooden or steel pallets. They provide long service life, high load-bearing capacity, and stable performance in brick production.

What sizes are available for GMT Pallet?

We can produce pallets in different sizes according to your brick machine model. Common dimensions range from 850mm to 1400mm width, Lengths from 300mm to 1350mm.and 18mm to 50mm thickness. Customized sizes are available upon request.

What is the price of fiberglass brick pallets for concrete machine?

The price depends on the size, fiberglass content, and order quantity. Higher fiberglass content means higher strength and longer service life, but also a higher price. Please contact us for an accurate quotation based on your requirements.

How do you ensure the quality of your pallets?

All pallets go through strict production and quality control processes. We test load-bearing capacity, bending resistance, and durability to ensure stable performance. Many of our pallets are already being used in brick factories worldwide.

What about delivery time, payment terms, and shipping?

Delivery time: Usually 10-15 days depending on order quantity.

Payment terms: T/T, L/C, or other agreed methods.

Shipping: By sea, land, or air. We can also work with your freight forwarder or provide door-to-door service if required.