The construction materials industry is witnessing growing interest in glass fiber reinforced brick pallets, especially for their performance in steam curing environments. Unlike traditional wooden or bamboo block pallets, these advanced pallets are designed with high strength and durability in mind.

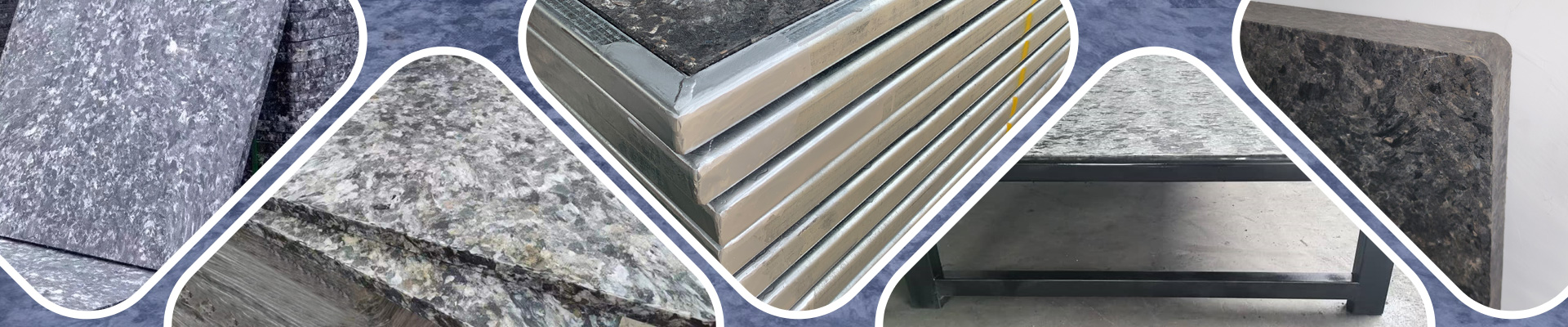

Manufacturers report that fiberglass brick pallets can maintain stability and shape even under high temperature and humidity conditions during curing. This feature is crucial for hollow brick machines and other automated block production lines where consistent pallet performance directly impacts efficiency.

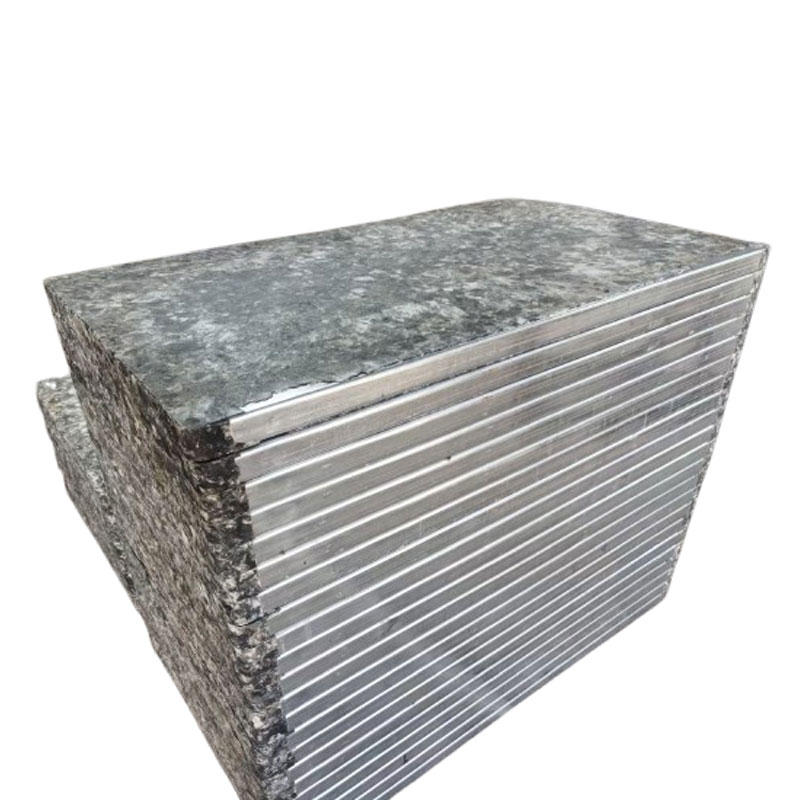

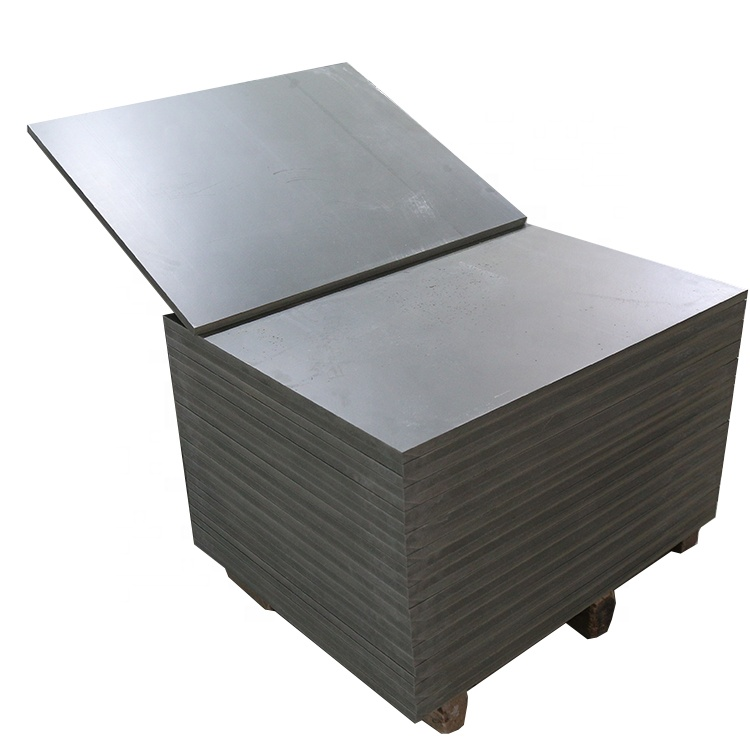

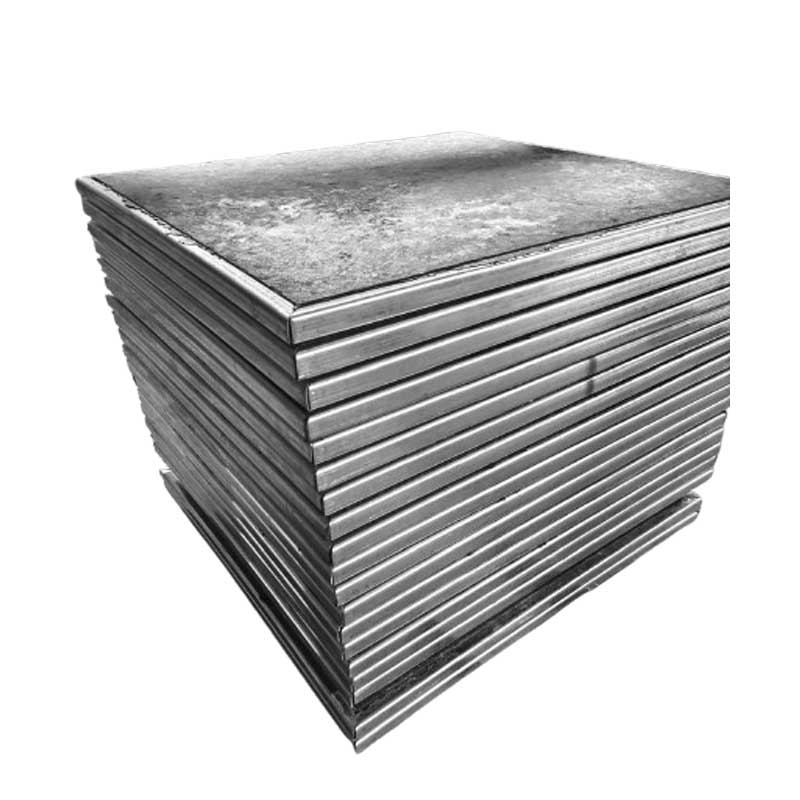

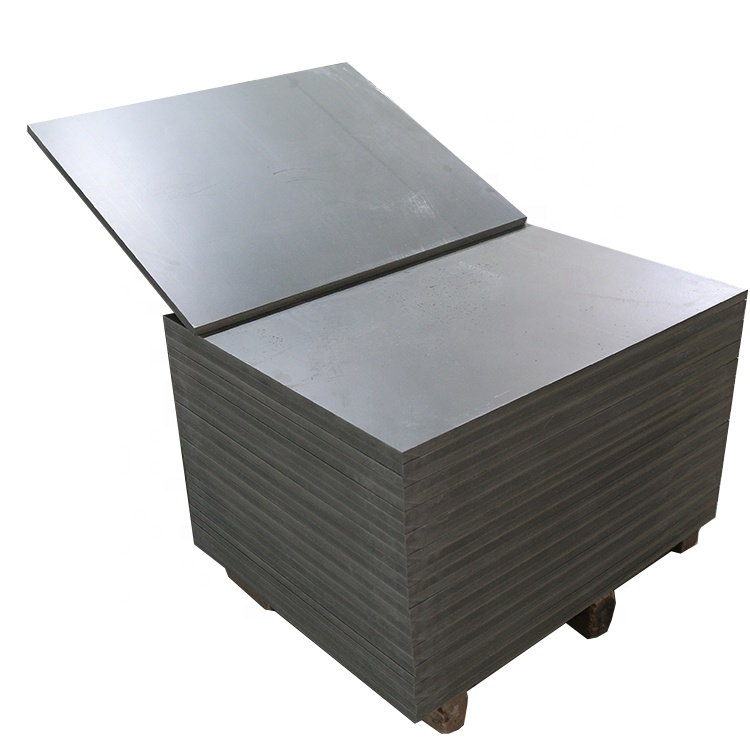

Compared with wooden brick pallets or PVC block pallets, the new composite brick pallet solutions show lower deformation rates, higher load-bearing capacity, and a significantly longer service life. Many block factories have confirmed that using fiberglass reinforced pallets can reduce replacement costs and improve long-term output quality.

Industry experts highlight that GMT block pallets and fiberglass brick pallet boards with customized thickness (such as 20mm or 25mm) are becoming a preferred choice for large-scale brick factories. In addition, suppliers are offering tailored solutions to meet diverse production requirements, from oversized pallet sizes to lightweight options for easier handling and shipping cost savings.

As the demand for durable and environmentally friendly materials grows, the adoption of glass fiber reinforced block pallets for steam curing is expected to expand across Asia, Africa, and Latin America. This trend underscores the shift from low-cost wooden solutions to high-performance composite materials in the global brick machine pallet market.