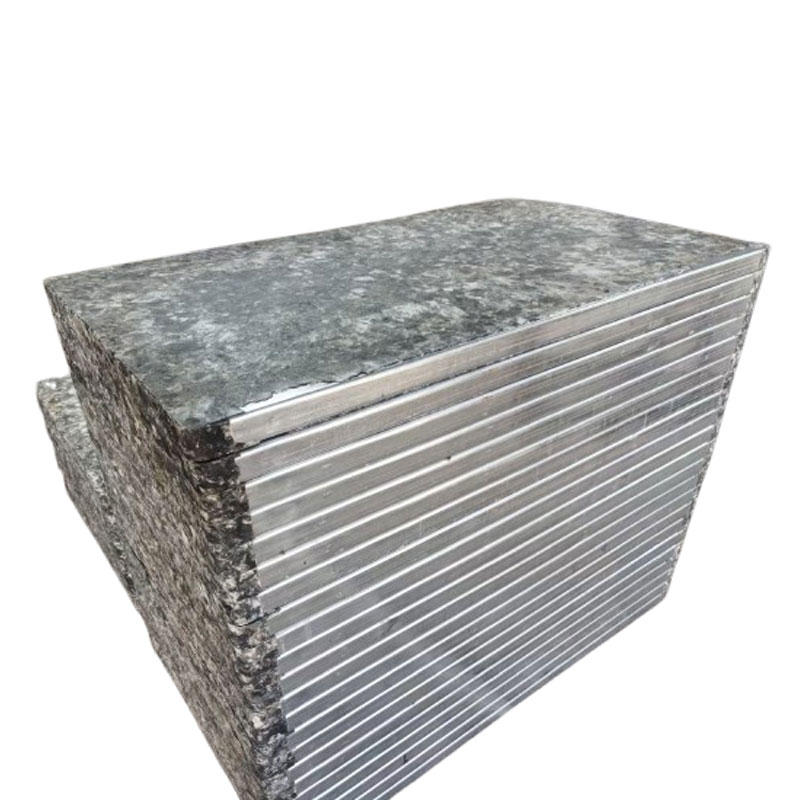

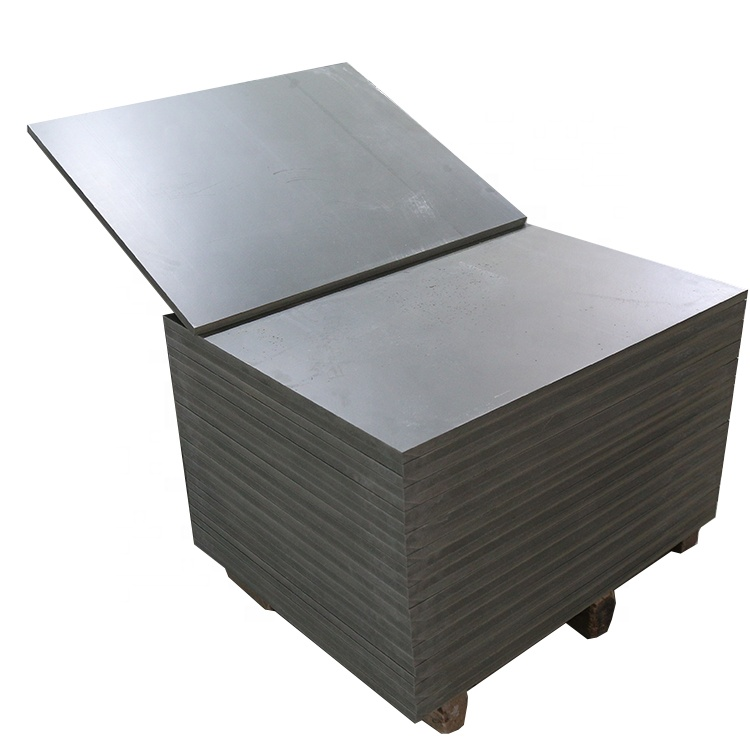

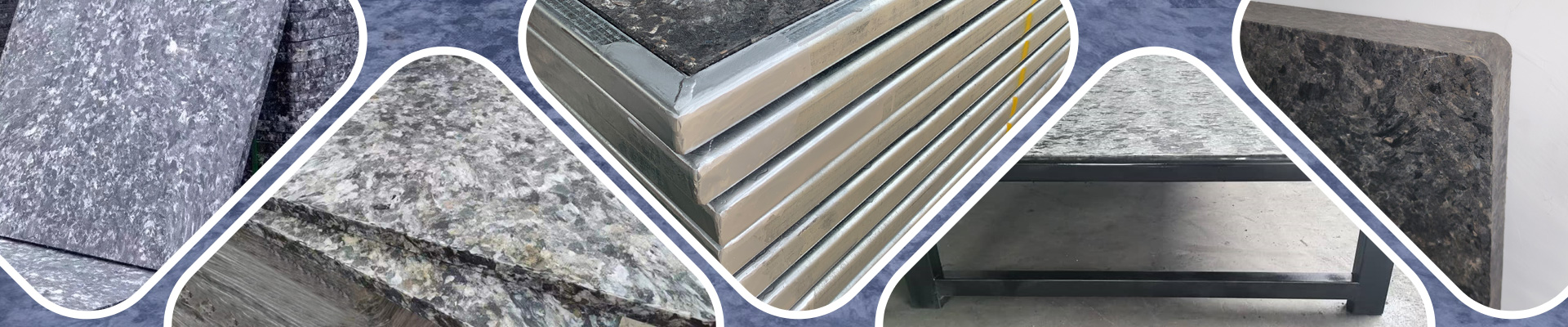

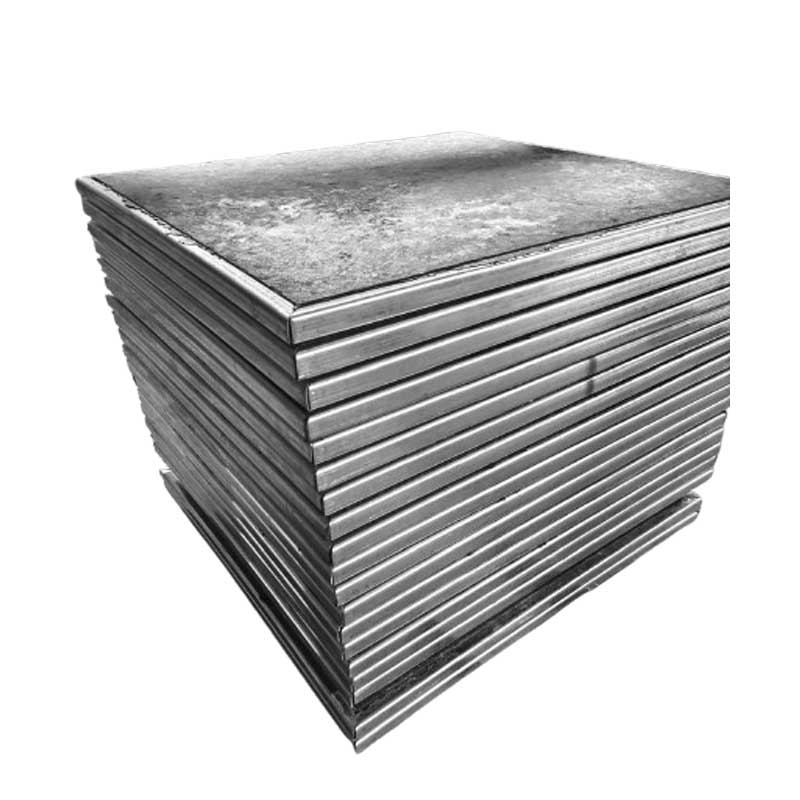

In the year 2023, our esteemed customer hailing all the way from Tanzania paid a visit to our factory. It was an interesting time as we welcomed them with open arms, eager to showcase our state-of-the-art manufacturing facilities and top-notch products. Back then, they had been relying on the traditional wooden pallets for their brick production process. These wooden pallets were quite common in the industry, but they also came with their fair share of drawbacks. For instance, they were prone to wear and tear over time, affected by moisture and various environmental factors, which could lead to issues like rotting and splitting. However, when our Tanzanian friends witnessed our meticulous production process, which was streamlined and efficient, and saw the high-quality product samples we presented, they were immediately intrigued. They decided to take a leap of faith and give our 50% black fiberglass pallets a try.

This decision was not made lightly, as they had to consider how these pallets would integrate into their existing production system and whether they could truly bring about improvements. Fast forward to two years later, which is now, and the performance of these fiberglass pallets has been nothing short of outstanding. There has been no sign of breakage whatsoever, even under the continuous heavy loads and rough handling that are often part and parcel of a busy brick production environment. Moreover, they haven't shown any deformation, maintaining their original shape and structure intact. The surface of the pallets remains as smooth as ever, which is crucial for ensuring the smooth operation of the brick production line and the quality of the final products. Their strength has also been remarkable, standing up to the test of time and the rigors of daily use. Our customer was absolutely delighted with the durability and stability of these fiberglass pallets when compared to the wooden ones they had been using before. The wooden pallets had often required frequent replacements and repairs, causing disruptions to their production schedule and incurring additional costs. In contrast, our fiberglass pallets had provided them with a seamless and reliable solution, allowing them to focus more on their core business of brick production without having to worry about pallet-related issues.

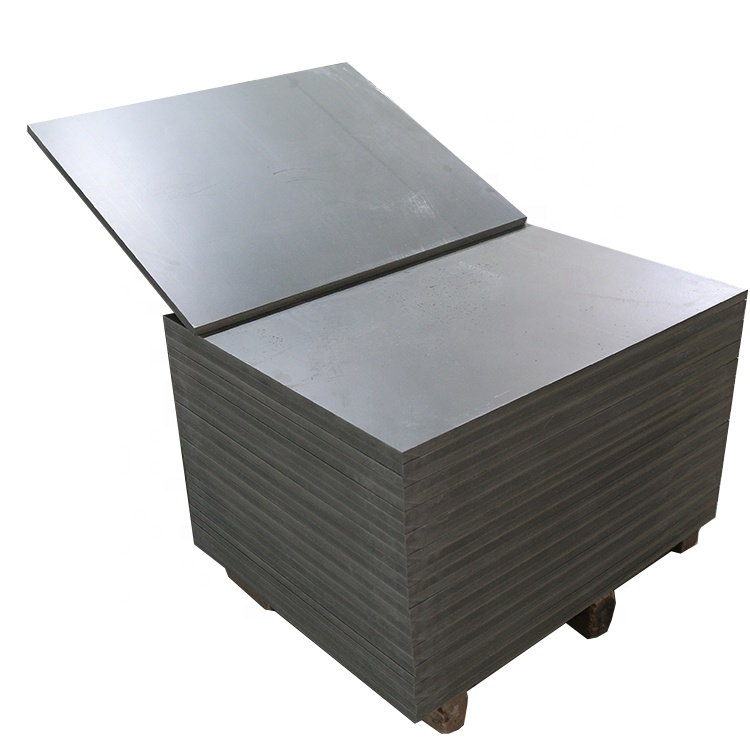

In 2025, buoyed by their extremely positive experience with our fiberglass pallets over the past two years, the customer made a significant decision. They placed a repeat order for 2,500 pieces of GMT Pallet. This decision was a clear indication of their trust in our products and their confidence that these pallets would continue to enhance their production efficiency and quality. By expanding their use of our fiberglass pallets, they aim to further scale up their production operations, meet the growing market demand for bricks, and ultimately boost their business growth. This real-life case serves as a powerful testament to the long-term value and reliability of fiberglass pallets in brick factories. It shows that when businesses choose innovative and high-quality materials like fiberglass pallets over traditional options, they can reap numerous benefits in terms of improved productivity, reduced maintenance costs, and enhanced product quality. It also encourages other brick manufacturers in the industry to consider making the switch and embrace the advantages that fiberglass pallets have to offer.